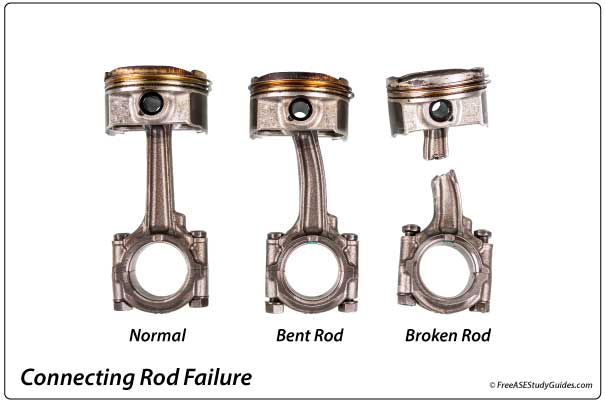

Connecting Rod Failure

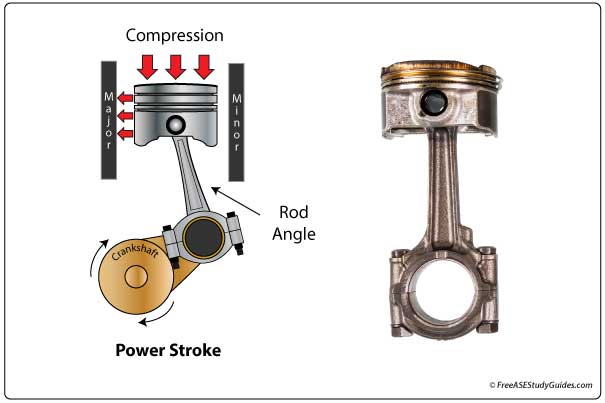

Connecting rods connect the piston to the crankshaft, are solid, made of hardened forged steel, and designed to last. Typically a bent rod is caused by overrevving, detonation, or fluid entering the cylinder and ending in a hydrolocked engine.

Initial Inspection

A slightly bent connecting rod may not be noticeable during the initial inspection. However, it may appear as one-sided diagonal wear on the skirt located on the major thrust side of the piston. A special tool holds the rod and piston; gaps and variations are measured with a feeler gauge.

Bent Connecting Rod

A bent connecting rod is usually the result of incompressible coolant or fuel entering the cylinder resulting in hydrolock. Never scratch or mark a connecting rod. After removal, screw the nuts onto the bolts to keep the two parts together.

Broken Connecting Rod

A broken connecting rod is catastrophic. Typically the momentum of the engine causes the broken rod to thrash around the engine causing unrepairable damage. Even scratching into one of these rods will weaken it, possibly ending in a thrown piston rod.