Carbon Buildup and Oil Coking

Low-quality fuel and oil result in carbon buildup in the engine and combustion chamber. Therefore, most fuels and oils contain detergents and additives that clean the carbon off the engine valves and combustion chamber.

The intake valves of multiport engines benefit from fuel washing across the valve, cleaning off dirt and fuel.

The intake valves in today's gasoline direct fuel injection engines do not have fuel washing over the valve. Instead, it is injected directly into the cylinder. As a result, carbon deposits on the intake build up and reduce engine power and lower fuel economy.

Low-quality oil or using the wrong type of oil can lead to carbon buildup. For example, many engines have oil jets that spray cooled oil under the hot piston. Low-grade oil can vaporize and get drawn back through the PCV system resulting in carbon buildup in the intake system. Recommended oil changes with the correct oil are essential to the life expectancy of any engine.

Oil leaking past the piston rings and valve seals results in carbon buildup. It impedes the movement of the rings and fills the end gaps.

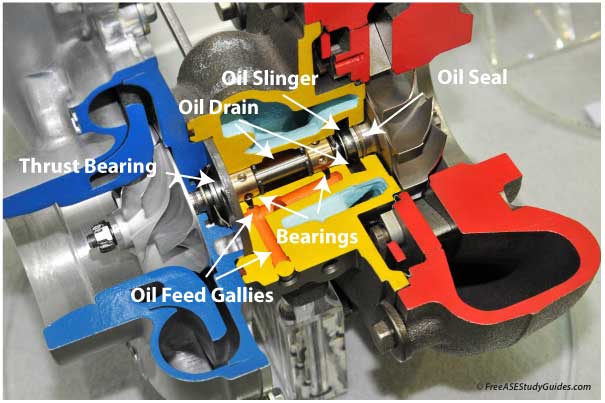

After shutdown, heat soaking into a turbocharger causes the oil to change and harden inside the seal. This process is known as coking. Turbo coking occurs when the engine first shuts down and there is no oil flow. Water-cooling and merely letting the engine idle and cool down can lengthen the turbocharger's lifespan.

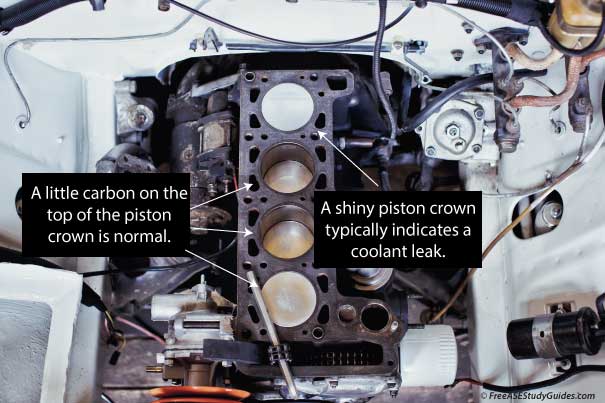

Coolant entering the combustion chamber vaporizes, resulting in white-gray exhaust. If the crowns of one or two adjacent cylinders appear new or "washed" clean. Coolant enters the chamber through the head gasket, cracked cylinder head, or engine block, softening the carbon and helping it break away from the piston and flow out with the exhaust.