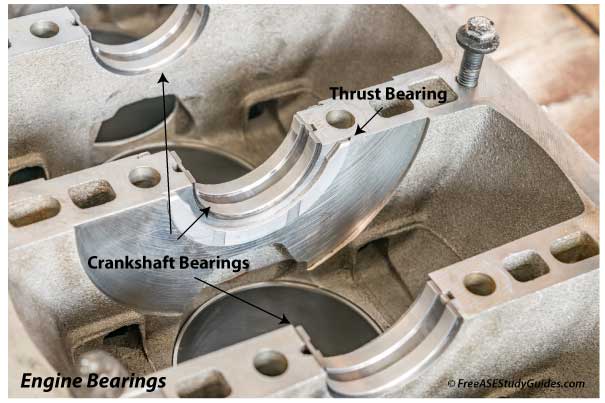

Thrust Bearings

Thrust bearings provide a specified amount of crankshaft end play. Worn thrust bearings result in too much crankshaft endplay; the crankshaft moves too far forward or backward in the engine block. Most fit into grooves formed in the block's webbing. Some engine manufacturers have these incorporated into the sides of the main bearing.

OEM bearings are typically aluminum alloy bonded to a steel alloy shell. Heavy-duty applications and high-performance engines have a copper/lead alloy because aluminum alloy bearings are less forgiving and, under heavy wear, can break into chips and pieces, get into the oil stream, and settle in the base of the oil pan.

Crankshaft End Play

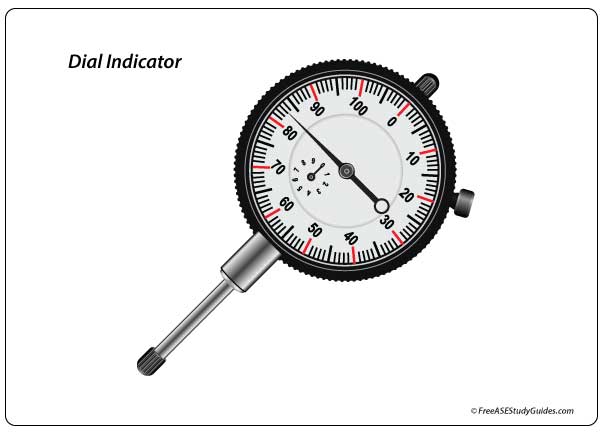

Measure crankshaft end play with a dial indicator against the harmonic balancer or flywheel. Prying the balancer or flywheel forward and backward indicates crankshaft end play.

These bearings do not wear as frequently as piston rings and rod bearings. Worn thrust bearings occur primarily in older vehicles with manual transmissions. Overloading and misalignment cause damage to these bearings. Excessive end play is evident after removing the oil pan. It damages and wears the crankshaft, main caps, and engine block where the crankshaft rides.