Enhanced Evaporative Emission Systems

Evaporative emissions were installed on vehicles in the late 1960s when they realized that 10-20% of hydrocarbon emissions occurred while the vehicle sat at rest. The basic systems installed on these early model vehicles were uncomplicated and vacuum-controlled. Enhanced EVAP systems on today's vehicles are computerized and typically diagnosed with a visual inspection, a multimeter, and a scan tool.

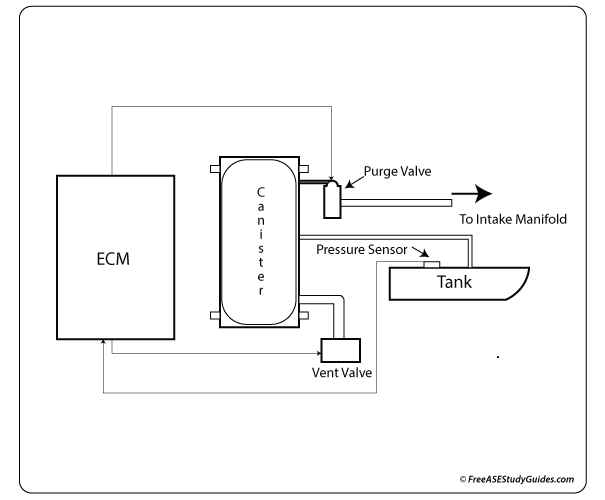

Charcoal Canister: The canister contains a charcoal insert that absorbs and retains fuel vapor until it's purged into the intake manifold for combustion. Late-model vehicles have an enhanced evaporative system equipped with a canister close to the tank to capture fuel vapor during refueling. The ECM typically purges the canister in gear after the engine has warmed and reached a specific temperature.

Purge Solenoid: The purge solenoid is responsible for venting the tank's fuel vapor into the intake manifold. The ECM only purges the system after meeting conditions like engine operating temperature and speed. A faulty purge solenoid can result in a rough idle and difficulty starting.

Fuel Tank Pressure Sensor: This is an input used by the ECM to indicate if the system is leaking into the atmosphere. This input and other sensor inputs determine if there is a fault in the tank's seal.

Vent Valve: The vent allows fresh air to enter the canister. The ECM also uses it to monitor purge valve operation. OBD II Enhanced EVAP systems contain a vent valve.