Adaptive Learning / Fuel Trim

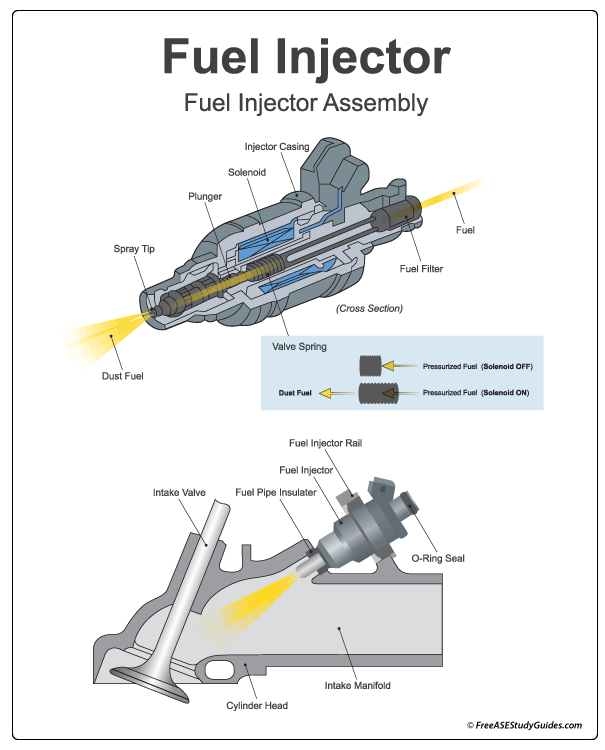

Fuel trim is a two-part adaptive strategy that adjusts fuel injector pulse width (open time) to adapt to wear, defects, or changes in the system. The two parts of a computer fuel trim adaptive strategy are short-term fuel trim STFT (additive) and long-term fuel trim LTFT (multiplicative).

Short-term fuel trim consists of temporary changes to fuel injector pulse width to compensate for a change in load, like climbing a hill, or changes in speed, like decelerating from highway speeds to an offramp.

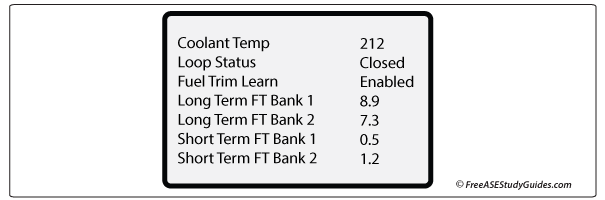

Long-term fuel trim is more permanent. The ECM will adjust the fuel trim to compensate for continuous operation in cold or high altitudes. For example, a disconnected vacuum hose causes the fuel trim to trend lean (positive 10%). Conversely, a dripping fuel injector results in a rich air-fuel ratio, causing the fuel trim to trend rich (negative -10%).

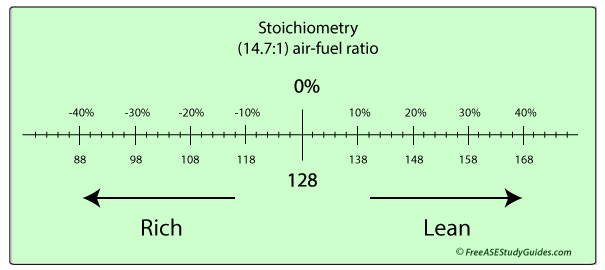

Some manufacturers use steps up to 256 to present fuel trim. The median or stoichiometry, a (14.7:1) air-fuel ratio, is 128. Numbers above 128 indicate a lean condition, and numbers below 128 indicate a rich mixture. It is typically out of range when the number exceeds 10 in either direction.

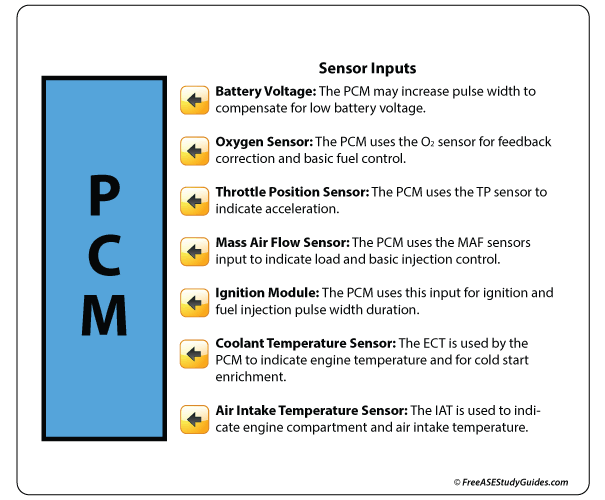

The vehicle's operator controls air intake into the engine's cylinders through the accelerator pedal, and the ECM controls the fuel required to meet these and other demands. It tries to maintain a long-term air/fuel ratio of 14.7:1. The injector on time is the result of sensor input and learned adaptive strategies implemented by the ECM.

The OBDII monitor monitors short and long-term memory. It sets a fault code when the vehicle emissions exceed 1.5 times the emissions standard. When STFT and LTFT exceed 10% or ten steps from 128 in either direction, the ECM is likely compensating for a faulty component, something beyond normal engine wear. The short- and long-term fuel trims must be out of range for the ECM to set a fault code.

The ECM makes adjustments based on data stored in short-term memory to calculate the fuel injector pulse width. It also uses the O2 sensor's input to monitor fuel trim. For example, if the oxygen sensor were frozen with an erroneous and constant output of 800Mv, the injector pulse width and air-fuel ratio would be affected.