Suspension: Strut Assembly

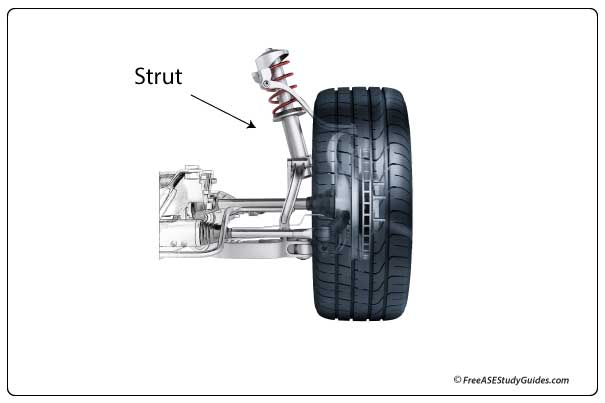

Struts and shocks prevent unwanted coil spring motion by forcing hydraulic fluid through tiny holes in a piston as it moves up and down inside its chamber. It provides resistance to its compression and extension cycles and prevents sudden movement. It isolates and protects the chassis and passenger compartment from bumps and irregular road surfaces. Without this dampening effect, the vehicle would feel like it's floating down the road.

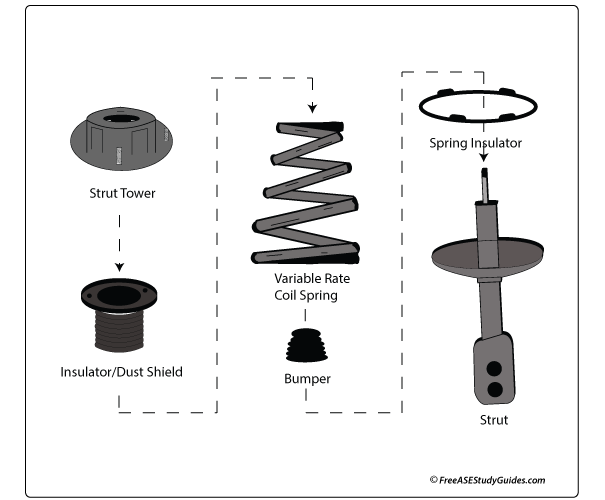

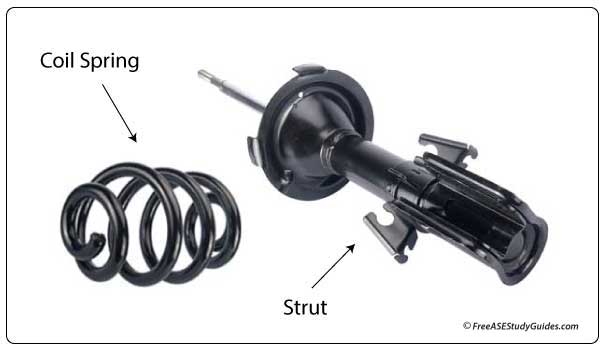

A strut combines a shock absorber and a coil spring. Designed by Earle S. MacPherson in 1947, it is now the most commonly used independent suspension found on vehicles today. A strut, like a shock absorber, prevents the coil from oscillating after it hits a bump in the road.

Typically, the coil spring is reused when replacing struts, and the strut/shock absorber is removed and replaced. A special tool is required to compress the spring. Most shops and dealerships have one mounted to the wall. Be careful; safety comes first. Compressed coil springs contain a considerable amount of energy.

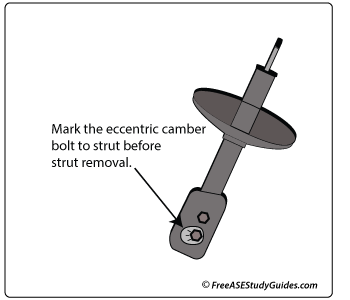

When removing a strut from a vehicle, check for any camber adjustments. If the strut has an eccentric camber bolt, mark its position before removal. Adjust both camber and toe when replacing this type of strut.