MAF and MAP Sensors

The ECM and the TCM monitor engine load through the MAP and MAF sensors. The (MAP) manifold absolute pressure sensor senses engine load through pressure in the intake manifold.

A faulty MAP sensor affects engine performance but can also affect the transmission's shift timing. This is because the PCM uses this signal to indicate engine load. Another sensor that indicates engine load and that also affects shift timing is the MAF sensor.

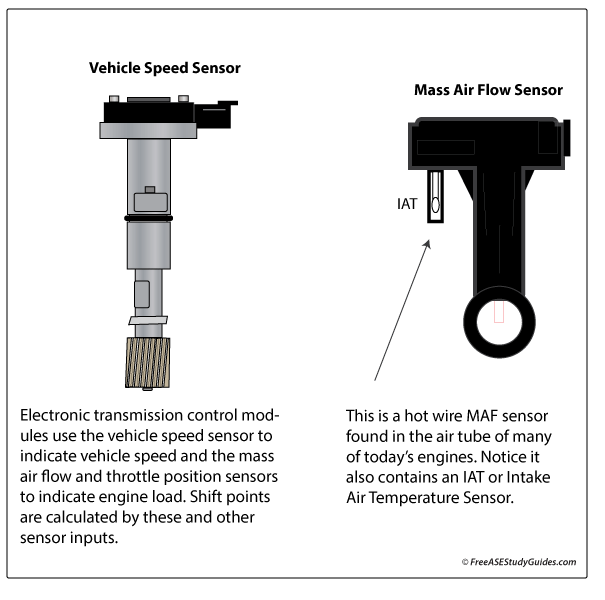

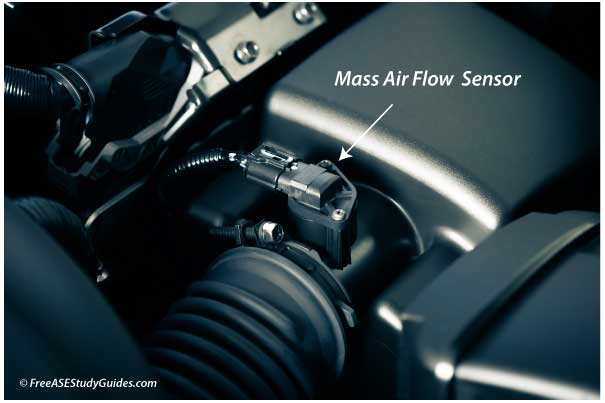

A (MAF) mass air flow sensor measures the volume of air passing through the air tube. There are several types found on vehicles today. These include cold, hot, Karmen Vortex, and vane-type MAF sensors.

The vane type MAF sensor uses a paddle or door that moves as air rushes by. This sensor utilizes a potentiometer (variable resistor) to send a variable or changing voltage signal to the PCM in proportion to air volume.

The cold wire MAF sensor uses thin metal strips that vibrate as the air passes by. This vibration changes in frequency, changing the signal sent to the PCM.

The hot wire MAF sensor contains a heated filament similar to a toaster element. The ECM increases and decreases current as cool air flows through the filament. The current to maintain the sensor's heat is converted into a voltage signal and sent to the PCM to adjust the air-fuel ratio.

Both the MAP and MAF sensors provide the PCM and TCM with valuable engine load information. The transmission control unit uses this information for shift control.