(CKP) Crankshaft Position Sensors

(EFI) Electronic fuel-injected engines use the (CKP) crankshaft position and (CMP) camshaft position sensor signal for ignition and injector timing. Distributorless ignition systems require a crankshaft position sensor.

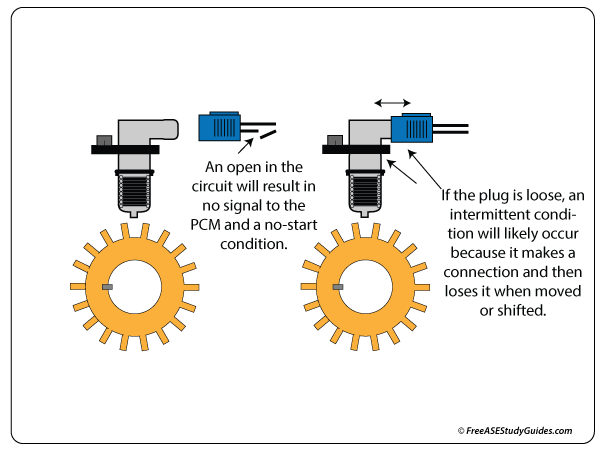

A loose plug on a crankshaft position sensor will result in an intermittent circuit, stalling, and a no-start condition. Because of the intermittent circuit, the engine will run one minute and not the next. The ECM would not get a consistent signal. A faulty sensor will result in the same stalling and no-start condition.

Check for spark with a sparkplug tester. If there is a spark at any cylinders, use a noid light to check the injector's pulse. If there is no spark or injector pulse, suspect a faulty crankshaft position sensor or ECM. This sensor affects both fuel and ignition timing.

Located behind the harmonic balancer, on the crankshaft, or on the flywheel, it can become contaminated from hot engine oil or coolant. Inspect the teeth on the sprocket and check the waveform with a scanner or oscilloscope to ensure amplitude and frequency remain consistent.

Use an ohmmeter to check the sensor's resistance compared to the manufacturer's specifications. The symptoms of a faulty crankshaft position sensor include no-start, intermittent stalling, and poor engine performance.