Steering Column Noise

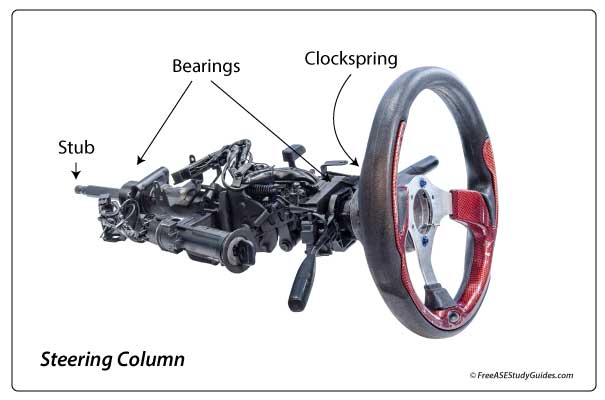

Steering columns and wheels typically have electrical issues, looseness, play, or problems with the tilt mechanism. They have a clockspring, universal joints, and a shaft with vibration insulators and bearings at the top and bottom. Any of these components can wear and cause noise.

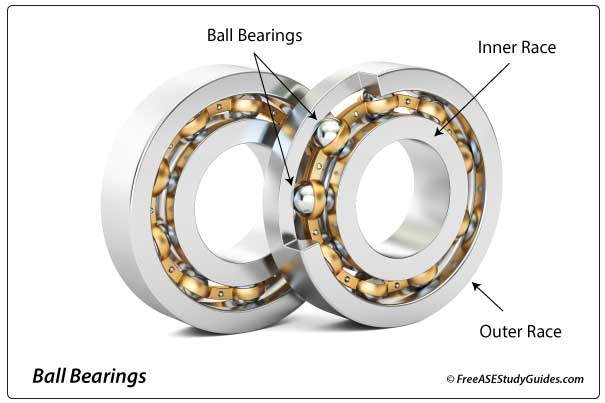

Steering Column Bearings

Most steering column bearings last the vehicle's lifespan. However, the bearings in older vehicles and trucks wear out, resulting in noise and a loose steering wheel.

When the wheel is turned, worn or faulty bearings cause a grinding or humming noise. A failed upper column bearing can result in an unsafe, wobbly steering wheel, making it difficult to steer the vehicle.

Clockspring

The clockspring maintains a constant connection between the airbag control unit and the airbag. They are made of plastic and contain a ribbon or wire that provides power for the horn, cruise control, radio, and many other accessories manufacturers have mounted in the steering wheel. They can wear out and can become noisy.

A failed clockspring results in an illuminated Airbag warning light. It can cause a grinding noise when turning the steering wheel. An open circuit will result in various codes and problems in cruise control, horn, and other systems incorporated into the steering wheel.

Replacing the clockspring will restore the circuit, and an enhanced OBD II scanner may be needed to clear the code and the warning light.

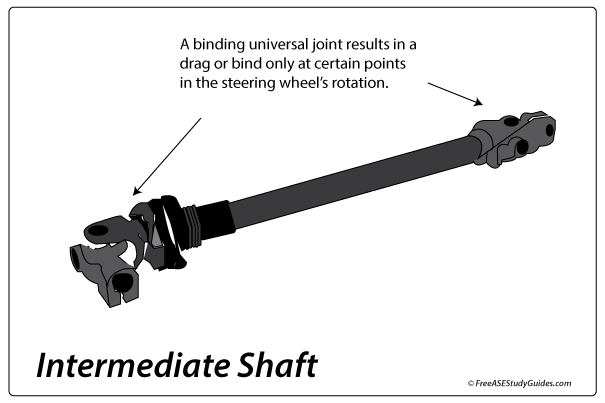

Universal Coupling

The steering wheel universal coupling or intermediate shaft is located between the end of the steering shaft and the pinion on the steering rack or gearbox. It can become worn and bind when turned, resulting in a clunking or popping noise. Have someone turn the steering wheel and watch for excessive or side-to-side movement in the universal coupling.