Tie Rod Ends

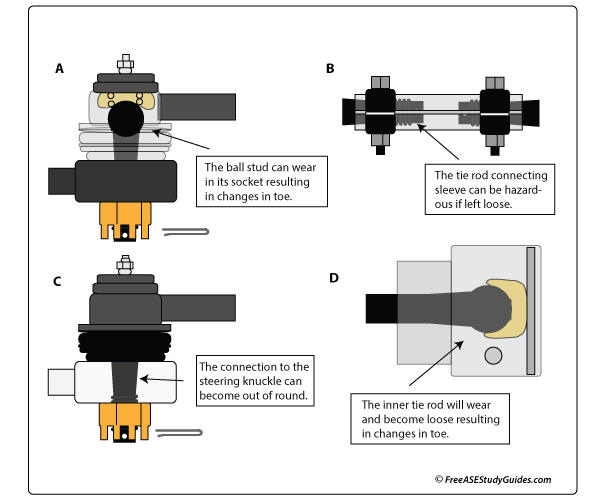

Tie rod ends connect the steering rack or parallelogram steering linkage system to the steering arm of a vehicle. They are designed similarly to ball joints, allowing up-and-down movement and rotating action.

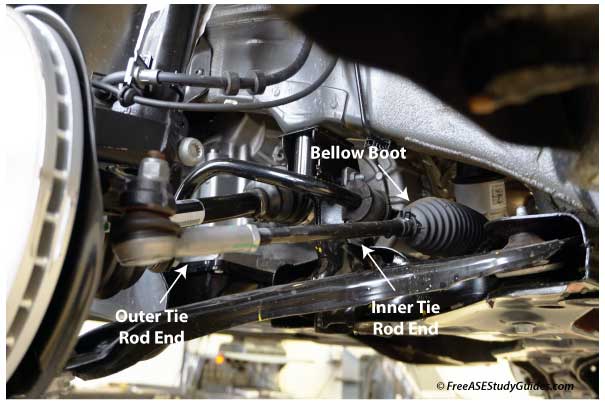

The inner tie rod is near the vehicle's center, and the outer tie rod is by the wheel attached to the steering arm. Rubber bellow boots protect the sockets of the inner tie rods from the environment.

Toe Adjustment

Fixed between the inner and outer tie rod ends, tie rod adjustment sleeves adjust the toe on parallelogram-type steering systems. Apply a little penetrating oil to the clamps, adjust the sleeve before loosening, and use a special rotating tool to rotate the sleeve without damage.

Steering Wander

Worn inner and outer tie rods produce noise, tire wear, and loose steering. The ball and stud have worn, resulting in slack and looseness. This looseness results in wander and constant correction of the steering wheel to keep the vehicle in its lane.

Feathered Tire Wear

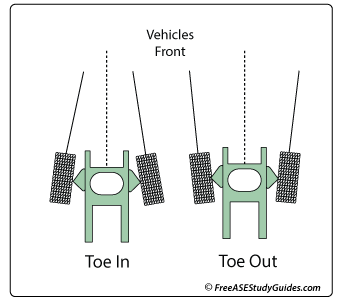

Loose tie rods result in diagonal tire wear and feathered treads. The changing toe angles cause tire tread damage as the tire travels down the road at an angle. Toe-in is when the fronts of the tires are closer together than the rears, and toe-out is when the fronts of the tires are further apart than the rears.

Loose Tie Rods

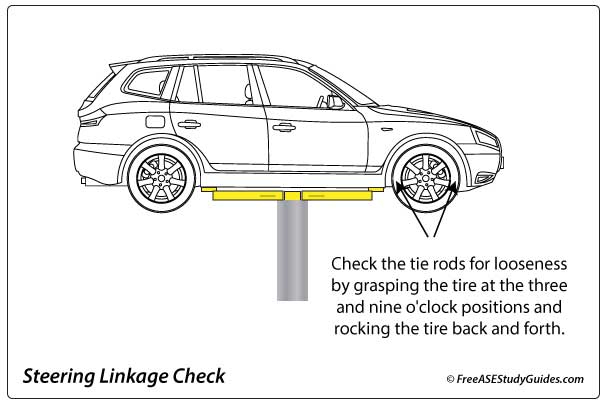

Grasp and rock the tire at the three and nine o'clock positions to check for loose tie rod ends. Grasp the tire at the twelve and six o'clock positions and rock it back and forth to check for loose wheel bearings.

Rear Toe Link

The toe setting of an independent rear suspension vehicle will affect the vehicle's thrust angle and result in excessive tire wear. Visually inspect the vehicle for bent or worn linkage. Manufacturers include a rear toe adjustment on vehicles with independent rear suspension.