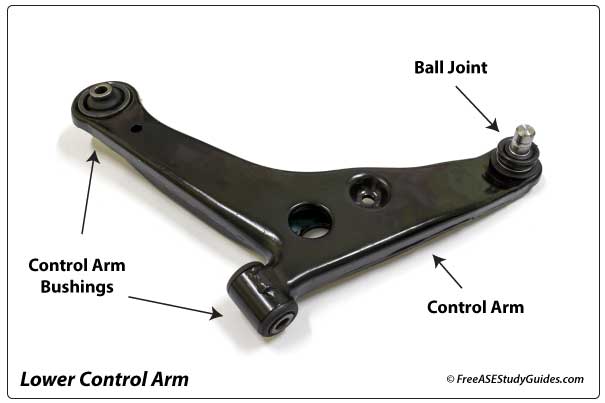

Control Arms

Control arms connect the vehicle's framework to the steering knuckle and wheel assembly. They are steel or aluminum capable of handling years of service. They are usually replaced because the vehicle struck a curb or deep pothole. However, control arm bushings and ball joints are the control arm pivots. They are serviceable parts that can wear and require replacement.

Control arm bushings are torsion bushings that allow for the twisting action needed as the control arm moves up and down over bumps in the road. They are hard rubber bushings bonded to two thick metal plates or dowels. One side of the bushing is attached to the frame, and the other to the control arm. They are firm and handle the control arms up and down movement while preventing vibrations from transferring to the chassis.

Control Arm Bushings

They get creeky when worn; the control arm will make a clunking sound as the vehicle accelerates, which disappears as it reaches cruising speeds. The vehicle may begin to wander or shimmy as alignment angles shift from this excessive looseness and play.

Worn Control Arm Bushings

A special C-clamp or a press with the appropriate adaptors is sometimes required to remove and replace these bushings. Most manufacturers require the control arm's final torque done with the vehicle at rest on the ground. Failing to do so will twist the rubber bushing while the vehicle rests, resulting in premature failure.

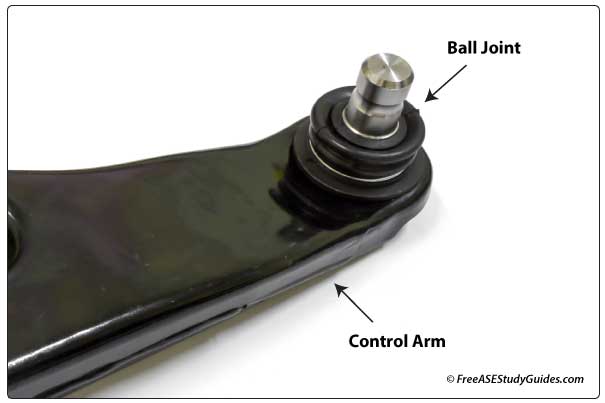

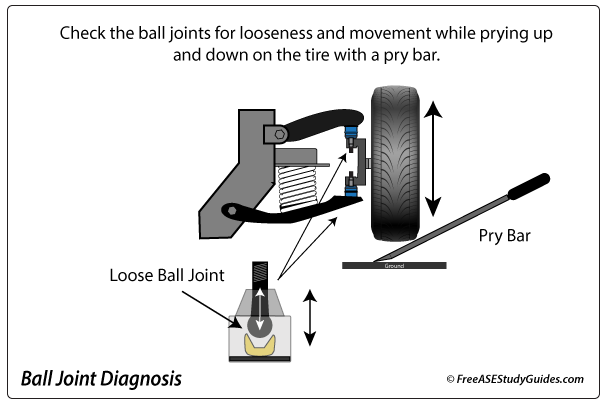

Worn Ball Joints

Sometimes, the ball joint is integral to the control arm, and a problem ball joint requires the replacement of the entire control arm.

Ball joints fasten the spindle to the control arm, providing a pivot point for steering and up and down movement. Worn ball joints make a thunking or popping noise when the vehicle hits a bump or turns at low speeds.