Leaf Spring Suspension

Leaf spring suspension has been around for a long time. Today they are found mostly on trucks and SUV's. They are located between the axle and the vehicle's frame, often accompanied by control arms and traction bars, to prevent up-and-down and side-to-side movement.

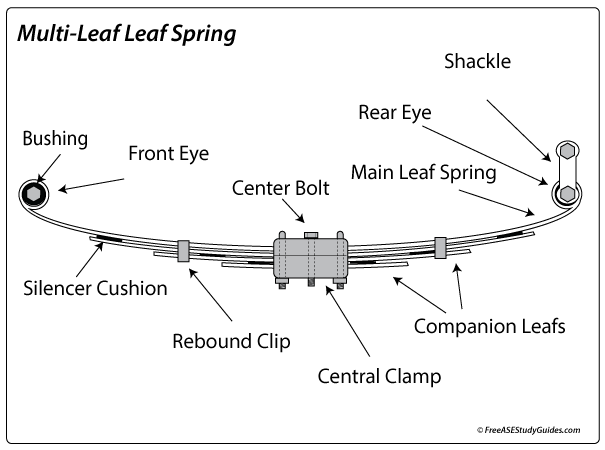

Multi-leaf leaf springs contain several leaves stacked on top of one another. They have plastics and other materials between the blades to prevent noise. As they wear, the leaf spring may begin to squeak and creak with movement or weaken and begin to sag, requiring curb height measurements. They are used in heavy applications instead of coil springs because they distribute weight across the chassis better.

Leaf Spring U-bolts

Leaf springs are made of steel and have a swivel shackle at the rear of the spring, allowing the spring to elongate if the vehicle carries additional weight or goes over bumps in the road. While inspecting the springs, look for cracks in the leaves.

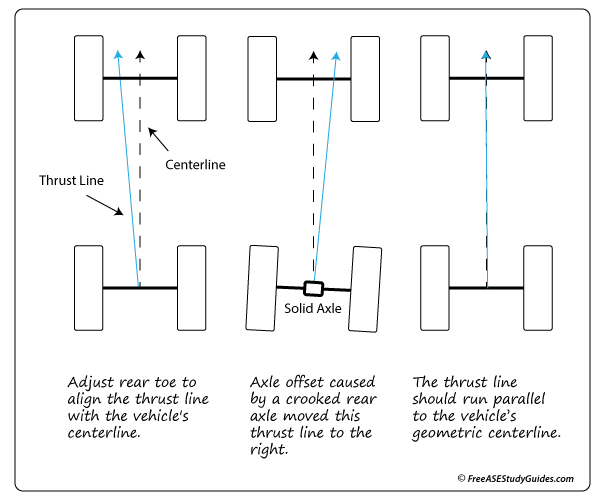

The U-bolts hold the leaf spring and center bolt tight. Loose and damaged U-bolts result in a broken center bolt or pin. The broken bolt causes excess movement, axle offset, and wheel setback. These symptoms affect the vehicle's alignment angles.

Removing and replacing leaf springs can upset the vehicle's driveline angles. A crooked axle and out-of-specification thrust angle cause an off-center steering wheel and dog tracking.