Valve Tip and Spring Installed Height

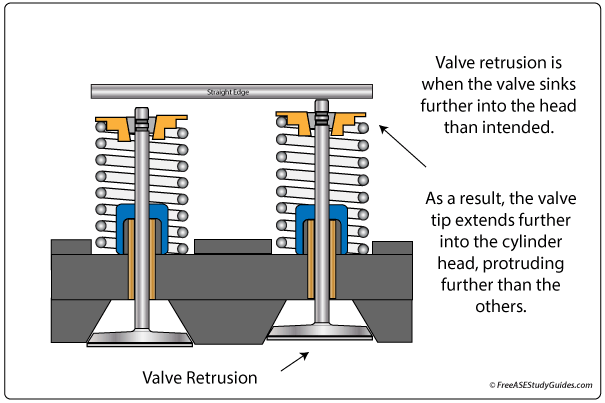

Valve retrusion is when the valve sinks further into the head than intended. This condition occurs over time or when removing material from the valve and seat during reconditioning.

This retrusion causes the valve to protrude further into the cylinder head, affecting the spring tension and installed height. Measure the valve tip and valve spring installed height and compare the readings to the manufacturer's specifications.

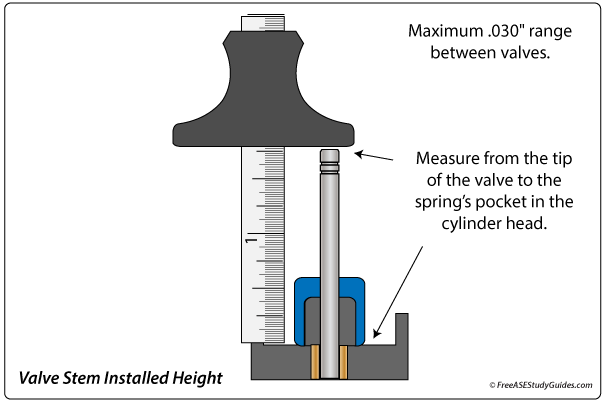

Valve Stem Installed Height

Use a machinist rule to measure the valve stem installed height. Measure from the valve's tip to the cylinder head's spring pocket. Typically the same amount of material is removed from the valve tip as from the valve and seat. Check with the manufacturer before grinding the valve tip. Some valves have hardened tips, and removing too much material will expose the softer metal to wear.

Valve Stem Height Gauge

Use a machinist rule or a special tool like a valve stem height gauge to take this measurement. Different size valve stem height gauges are used for different engines. It depends on how far the valve tip extends from the cylinder head. These tools are usually sold as a set. The dial gauge is fastened to the different measuring bodies by the alan key.

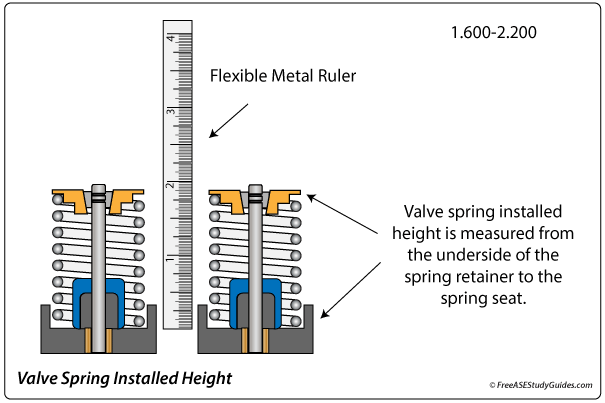

Valve Spring Installed Height

Measure valve spring installed height with a simple machinist rule or a valve spring height micrometer. The valve spring installed height is measured from the underside of the spring retainer to the spring seat.

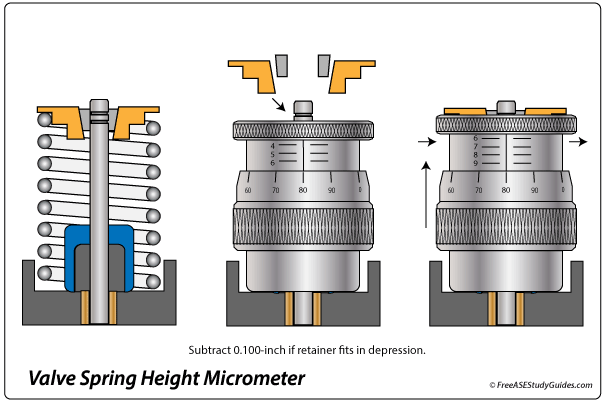

Valve Spring Height Micrometer

Remove the spring and install the valve spring height micrometer over the valve stem, and with the retainer and locks installed, turn the barrel to display the valve spring installed height.

Valve spring height affects spring tension. A tight spring will cause premature wear and a loose spring results in valve float and a noticeable drop in performance at higher engine speeds.