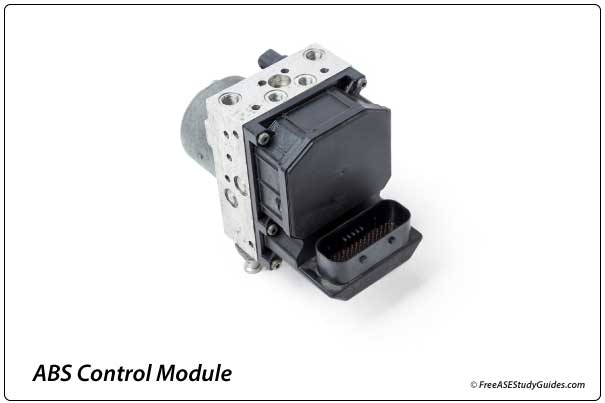

ABS Control Module

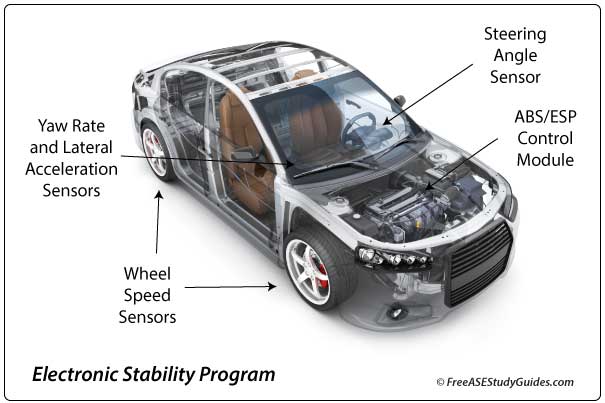

The Anti-lock Brake Control Module is the system's computer. It receives wheel rotational input from the wheel speed sensors. It controls the hydraulic valve assembly if an impending wheel lockup is detected and is an essential member of the ESP system, preventing wheel lockup during heavy braking to avoid hydroplaning and tire skid to help maintain vehicle steering and stability.

The control module runs diagnostic tests and controls the valves in the hydraulic modulator. When a failure is detected, the system is disabled, and the module illuminates the ABS warning light. ABS is vital to the vehicle's stability control system, and control module failure may also affect the traction control system.

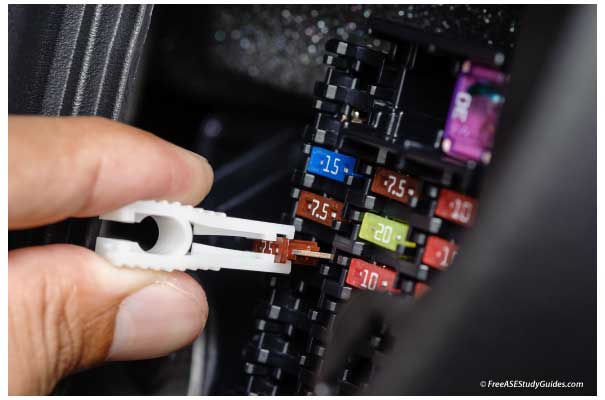

An OBD II scanner will point to the area needing attention. Typically, a fuse has blown, or a wheel speed sensor has failed. The system has two fuses: one for the control module and one for the electric pump.

If the control module's circuit continues to burn the fuse, inspect the wiring for damaged insulation. Use a multimeter to check the electric pump for internal shorts or opens and check the wiring for continuity.

The fault code U0121 indicates a loss of communication with the CAN network. The control module, the modulator, and the connector are in the engine compartment and exposed to this environment. Therefore, the problem may be the controller, resistance, or an open or short circuit.

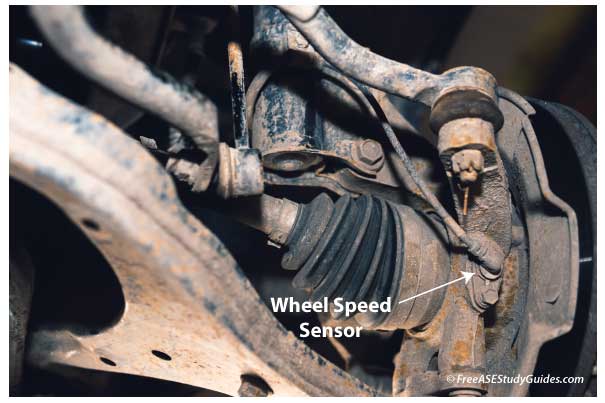

Wheel Speed Sensors

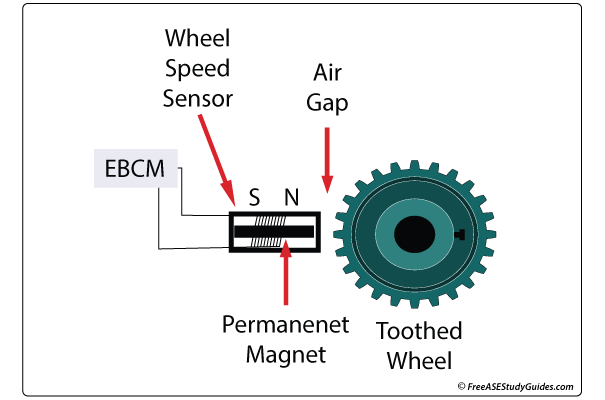

Today's vehicles have four-wheel speed sensors, but older models can have one, two, or three sensors. The ABS controller uses wheel speed sensors to detect the rotational speed of each wheel. They're a permanent magnet sensor, a coil of wire wound around a metal core.

The magnetic lines of flux created by this sensor change as a toothed ring rotates past its tip. They create voltage pulses that increase with wheel speed. Test the sensor with the multimeter set to AC voltage. The voltage signal on the multimeter's display should fluctuate while rotating the wheel.