ABS Accumulators

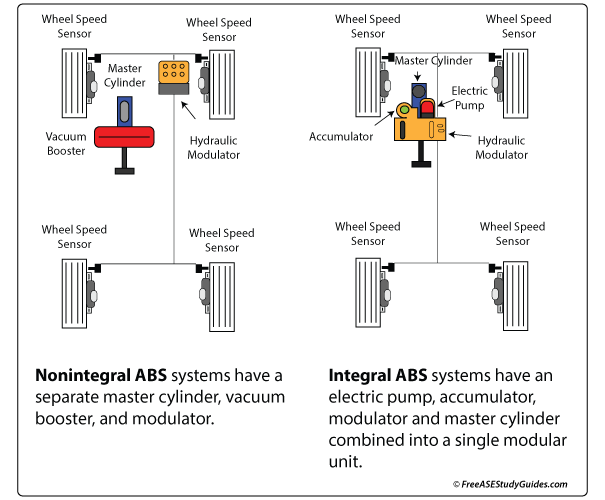

ABS accumulators store and hold hydraulic pressure for the system hold-release-reapply cycle. They are used on both integral and non-integral ABS systems. An integral unit includes an electric pump that provides high-pressure power assistance and pressure for the hold-release-reapply cycle. Many non-integral systems use a 50 psi spring-loaded accumulator to provide pressure for the cycle.

An integral ABS unit contains the master cylinder, modulator, electric pump, and accumulator in a modular assembly. The electric pump is operated by a relay that receives a control signal from the ABS control module. These pumps create pressure for the hold-release-reapply cycle and typically provide pressure for brake assist. The accumulator stores pressure for the system.

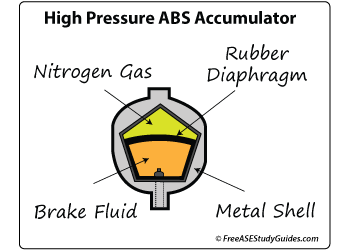

They utilize a nitrogen gas charge separated from the pressurized hydraulic fluid by a thick rubber diaphragm. When filled with pressurized fluid from the pump, these accumulators can reach dangerous pressures and must be handled carefully. They are depressurized by pulling the relay and pumping the brake pedal 25-40 times. Always check manufacturer service manuals and TSB's before repairing any ABS brake system.

An integral high-pressure accumulator has a low-pressure and a high-pressure switch. These switches allow the ABS control module to keep the pressure between a set parameter. The parameters vary, usually between 1000 psi and 1600 psi. The control module will illuminate the amber ABS light when pressures get too low. Some high-pressure accumulators reach pressures as high as 2700 psi.