Air Door Actuators

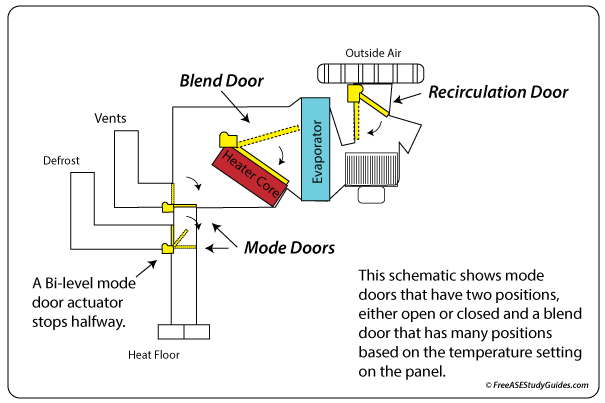

Air conditioning cases contain air doors that control air flow through the system. The basic air conditioning system has at least three diverter doors and one blend door. Diverter or mode doors are typically either open or closed, while blend doors that mix air have many positions.

Cables were used in older models to control mode and blend doors. These were replaced with vacuum motors and electric actuators. Vacuum-operated controls are great for doors that are either open or closed. The outside air recirculation door is an example of a door that is often vacuum-controlled. An air blend door needs precise control. Electric stepper motors with many positions (0 – 255) are used to achieve this control.

When closed, the blend door blocks air from passing through the heater core, providing maximum cooling. As it opens, it allows more and more air to pass through the core; mixing the air provides the desired temperature.

Electric actuators often require replacement for making a clicking sound in operation. As they wear, the endpoints change, or the plastic gears inside the actuator break and strip.

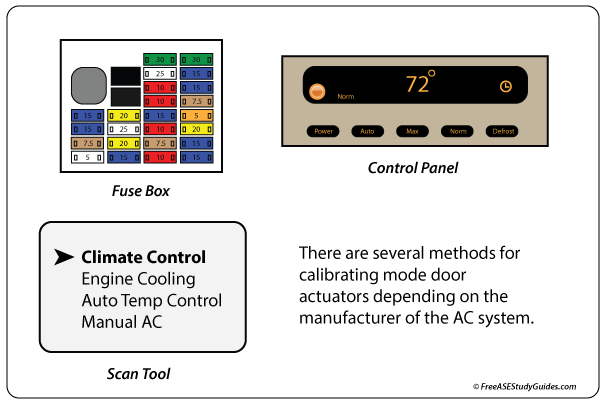

When replaced, they typically require calibration. The actuator motor contains a controller that receives a voltage signal from the main controller.

The method used to calibrate the actuator depends on the manufacturer. Some systems have a procedure that involves momentarily removing and replacing the HVAC fuse and waiting a specified time while the motors move from end to end and synchronize with the controller. Some require the technician to press and hold two buttons on the panel while the motors calibrate. The climate control mode of a scan tool is used to calibrate new vehicles with automatic climate control systems.