Checking and Measuring Brake Drums

Brake drums are cast iron or aluminum lined with steel or iron. Both of these materials lose their integrity from excessive heat. Drum brake systems convert energy in motion or kinetic energy into heat energy through friction. It is also true that brake shoes reach temperatures over 450° F. As the temperature rises, the braking system loses efficiency. Some brake drums have outer fins that help transfer heat energy to the atmosphere.

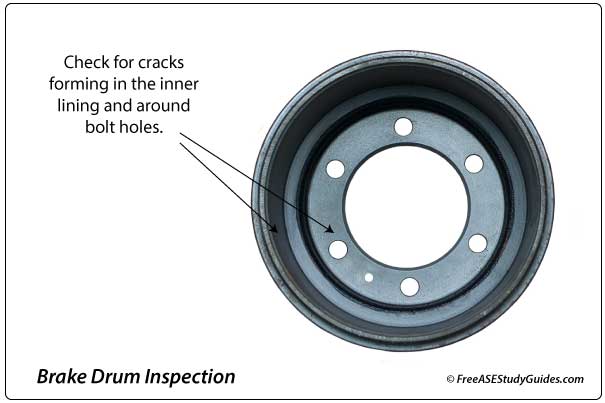

Discard a brake drum if it is beginning to crack. Small cracks lead to big ones, which may be deeper in the cast than it appears. When resurfacing a drum, always use a brake drum silencer band to reduce chatter marks caused by vibrations inherent to the process.

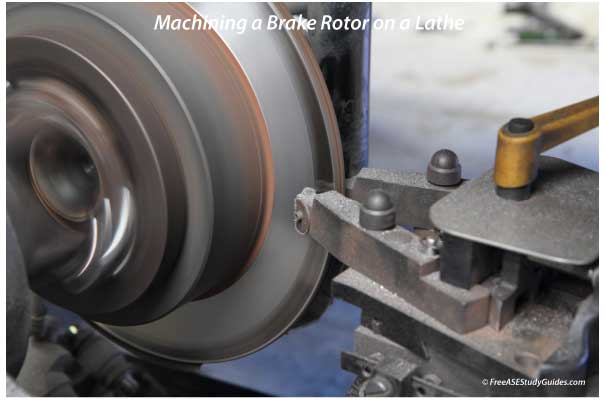

As the brake drum wears, minor pitting and warping will occur. Remove minor imperfections by resurfacing the inside surface of the drum. Resurface brake rotors and drums on a brake lathe. Before resurfacing a brake drum, locate the MAX DIA (maximum diameter).

Never cut a drum out of these specifications. They apply to the drum's inner surface after machining on the brake lathe, not before. Machining a drum removes some of its material. Replace a brake drum cut below discard (MAX) specifications.

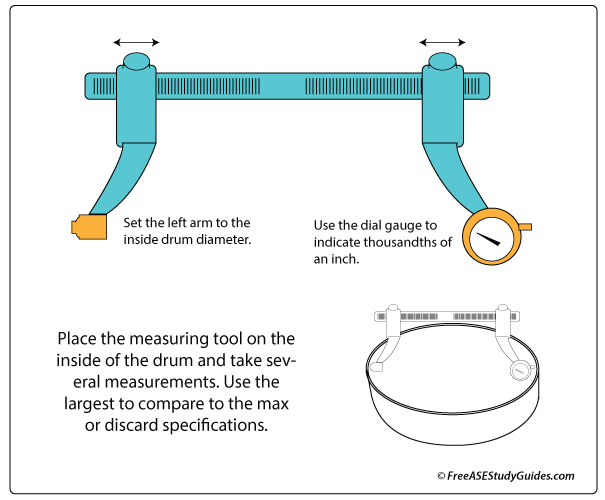

Measuring the inside of a brake drum requires a drum gauge or brake drum micrometer. Take measurements in several different spots around the inside surface of the drum and use the largest reading. Drums lose their original shape and become barrel-shaped or rounded in the middle. A bell-shaped drum has excessive wear on the outside edge.