Measuring Brake Drum Inside Diameter

Manufacturers install cast iron or iron-lined aluminum brake drums in vehicles with rear drum brakes. They are strong and made to absorb a lot of heat. However, they can become out of round or wear beyond the maximum specifications.

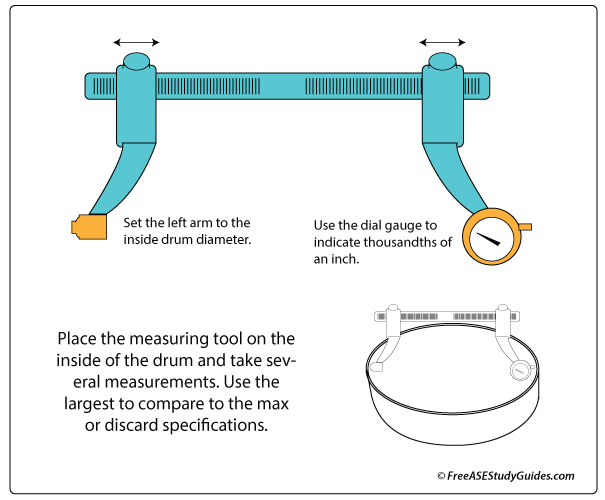

Measure the inside of the brake drum before deciding to discard or resurface it on a brake lathe.

Use a drum micrometer or an equivalent tool to retrieve these measurements. Compare them to the diameter stamped on the outside of the drum. If the drum is scored or grooved, place the gauge into the deepest part of the groove.

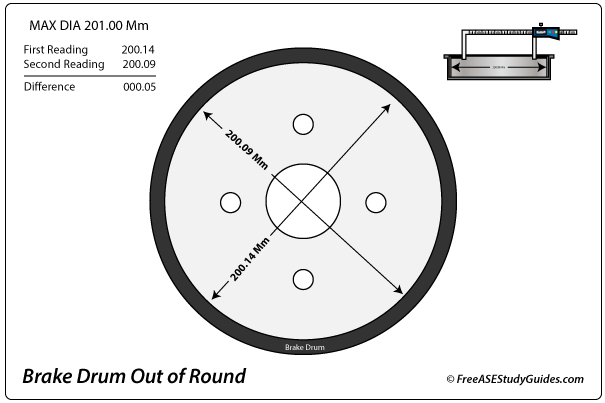

Take several measurements around the drum and use the highest or largest one retrieved. Then, compare it to the MAX "maximum diameter" stamped on the outside of the drum. If one of the readings is larger, the drum is out of round. Resurface a slightly out-of-round brake drum as long as it is within specifications. Replace the brake drum if the reading exceeds the maximum diameter.

Some passenger cars and light trucks have drum brakes installed on the rear. An out-of-round brake drum results in a vibration felt in the seat while braking and hot spots on the inner lining where one or two areas heat more rapidly than the rest of the drum. Heat checking and hot spots result in martensite and cracks seen during an initial visual inspection. Replace a cracked brake drum.