Brake Metering Valve

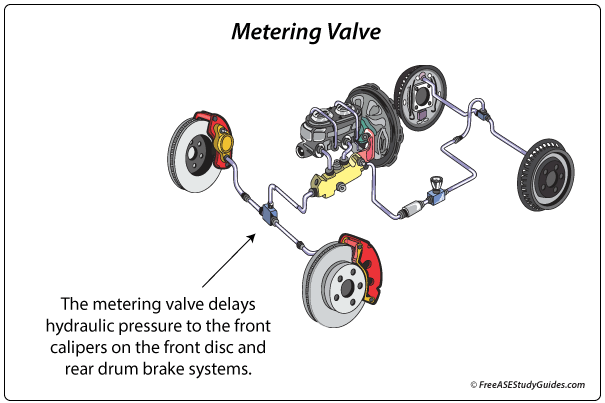

Rear drum brakes have springs that have a considerable amount of force. On the contrary, front brake calipers apply easily and have no spring pressure to overcome, creating an imbalance between the front and rear brakes. The metering valve holds hydraulic fluid pressure to the front calipers until the rear brakes apply. This delay produces a balanced application of the front and rear brakes.

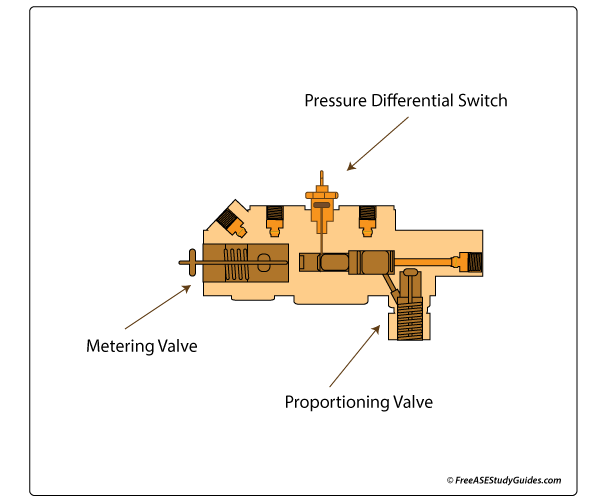

The brake metering valve, similar to the proportioning valve, works to achieve balanced braking. The combination valve often contains these valves along with the brake warning switch.

Most FWD diagonal-based brake systems in passenger cars do not use a metering valve. Neither do four-wheel disc brake systems; expect to see this valve on the front disc and rear drum brake systems.

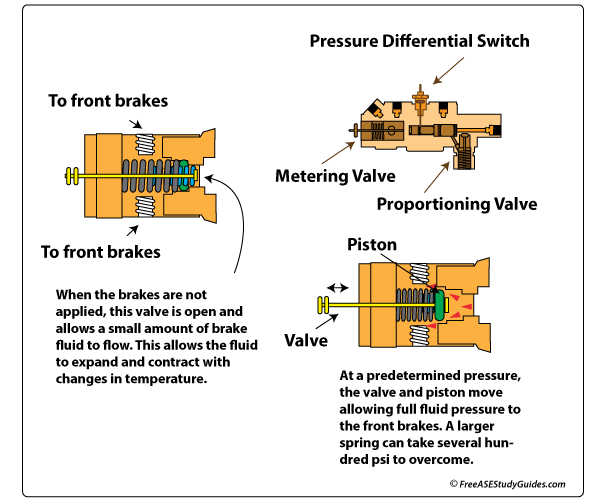

It's in line with the front brakes and holds back pressure to the front calipers until enough pressure builds in the system. The rear brake apply pressure builds to a point (75-125 psi) that forces the valve open, allowing pressurized brake fluid to flow to the calipers and then applying the front brakes.

The metering valve has an inlet port from the master cylinder and a port for each front caliper. A spring maintains pressure on a sealed port, blocking fluid pressure to the front brakes. As pressure builds past spring pressure, the valve stem moves until it reaches a hold-off point. At this hold-off point, the brake fluid is allowed to flow freely.

Metering Valve Symptoms

The front brakes produce up to 70% to 80% of a vehicle's braking. As a result, a stuck open metering valve can result in a nose dive condition. Conversely, if the valve sticks closed, the car loses stopping power because the front brakes do not receive full pressure.