Brake Proportioning Valves

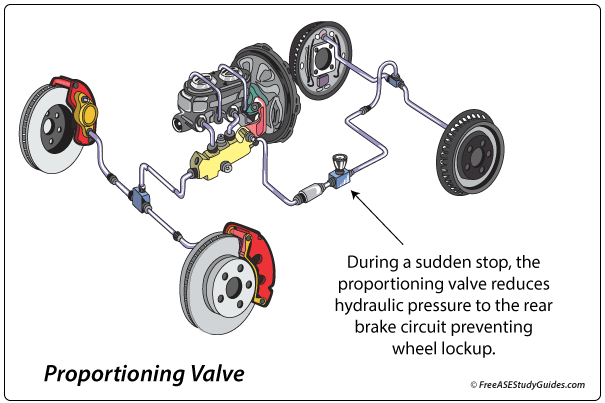

Proportioning valves enable balanced braking by reducing hydraulic pressure to the rear brake units during sudden and panicked braking. This reduction in pressure helps prevent rear-wheel lockup. During braking, most of the vehicle's weight is shifted to the front, leaving the rear with little traction. Many of these valves are integral to the combination valve on front disc rear drum brake systems.

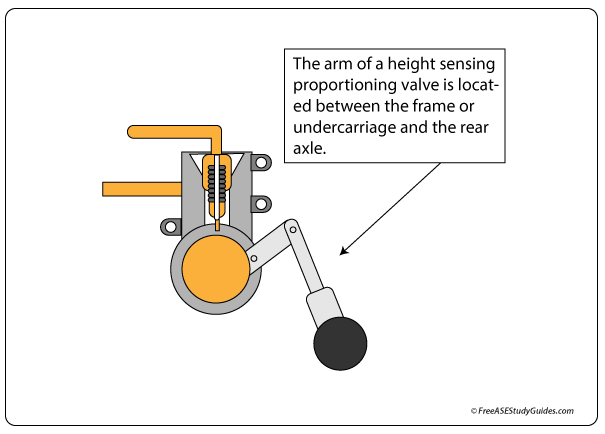

All height-sensing valves utilized the vehicle's ride height to regulate hydraulic pressure. Install the valve at vehicle ride height unless the manufacturer's specifications dictate otherwise. These brake valves reduce hydraulic pressure to the rear brake circuit if there is a sudden stop, preventing wheel lockup. If the valve is faulty or the brake shoes are contaminated and grabbing, the rear wheels will lock up during hard braking.

If the vehicle is raised higher than the specified with springs or a lift kit, increased ride height and reduced rear hydraulic pressure could harm brake performance. The linkage sits between the axle and the frame. The valve reduces pressure as the axle and frame move further apart, allowing the wheel to spin more freely. This type of valve is popular with manufacturers of pickup trucks.

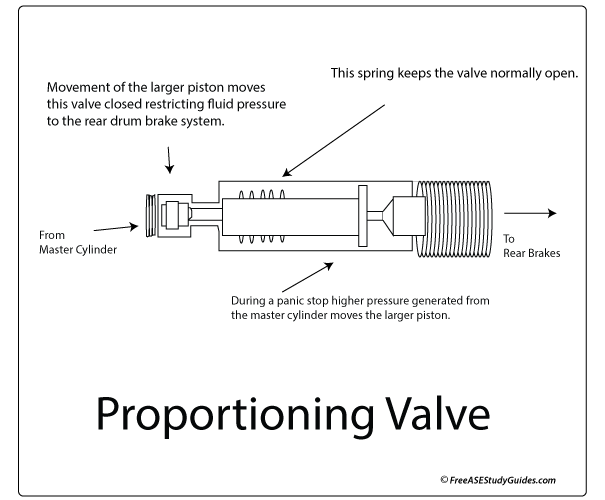

Spring-loaded piston-type proportioning valves are attached to the master cylinder or the line leading to the brake circuits. These systems cycle back and forth to maintain the required pressure on the rear brakes. They have spring-loaded pistons with different diameters at the ends. The size of the piston dictates the pressure reduction.