A Kinked or Restricted Brake Line

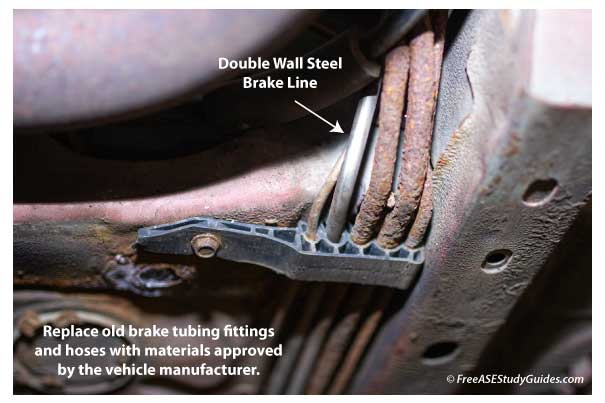

A visual inspection typically reveals the problem. If the brake line is rusty or damaged, replace the entire length with one approved by the vehicle's manufacturer. Compression fittings and copper (100%) tubing can rupture from pressure, and copper fittings can leak. Most manufacturers use coated double-wall steel tubing for their brake lines. However, some manufacturers and fabricators use nickel-copper alloy tubing that bends and flares more easily than steel and stainless steel.

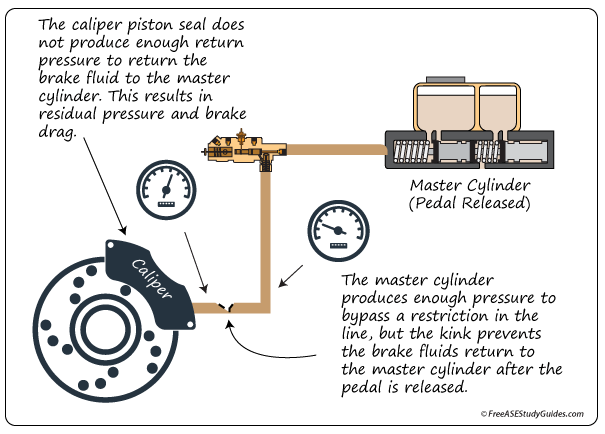

When a restriction forms in a brake line, the master cylinder creates enough pressure to bypass the kink and apply the brake. The problem is that the brake caliper or wheel cylinder cannot generate enough force to bypass the restriction and return the fluid to the master cylinder. This residual pressure results in brake drag.

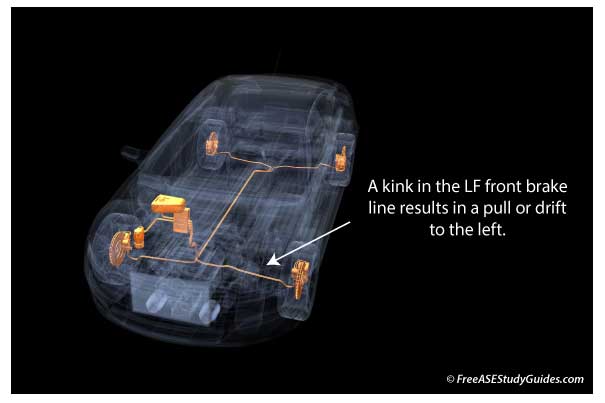

A kink or restriction in the LF front brake line results in a pull or drift to the left. This drag causes a significant amount of heat friction. Therefore, be careful while inspecting a brake assembly that has been dragging.

A Twisted Brake Hose

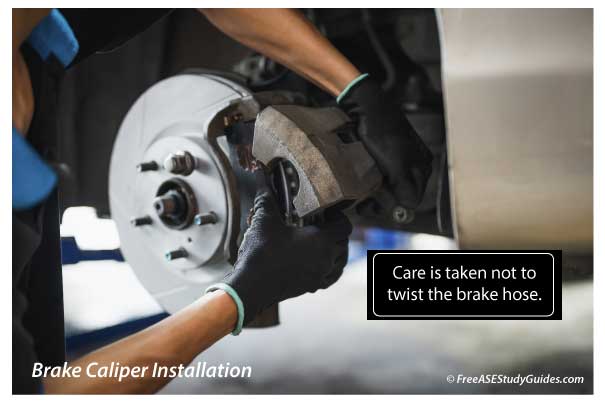

Twisting around the brake caliper during installation also twists the brake hose. A twisted brake hose causes the same problem as a kinked or restricted brake line. The dragging brake caused by the twisted hose should be noticed leaving the service bay.