Vacuum Brake Booster Test

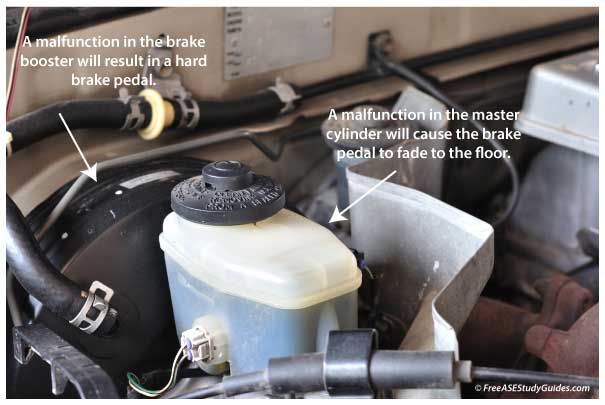

Vacuum brake boosters require a vacuum source and a tight seal to operate correctly. Typically, a loss of vacuum or a faulty brake booster results in a hard brake pedal. This symptom differs from a defective master cylinder, usually resulting in an internal leak and a spongy, soft brake pedal that fades to the floorboard.

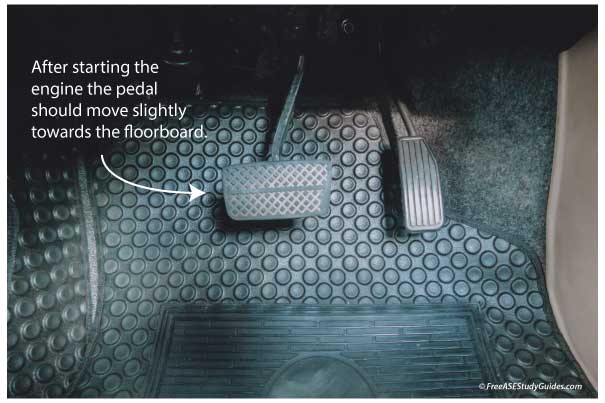

Most testing procedures for vacuum brake boosters are straightforward. First, begin the test by pumping the pedal with the engine off to deplete the brake booster of any residual vacuum. Next, keep your foot on the brake pedal and start the engine. The brake pedal should move towards the floor, usually about ¼ inch. If there is no movement and the brake pedal remains firm, suspect a problem with the brake booster or its vacuum source.

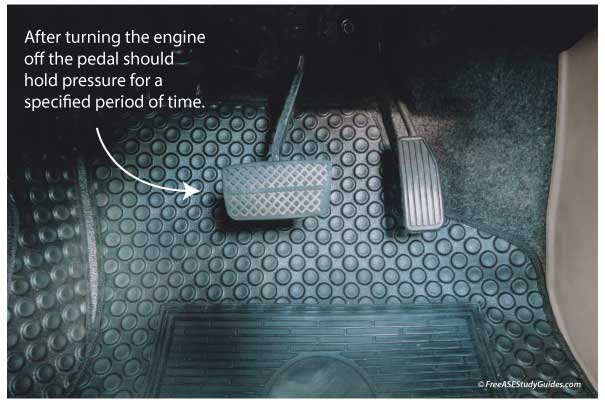

To check the booster’s diaphragm, some manufacturers recommend running the engine until it reaches operating temperature and holding your foot on the brake pedal while turning the engine off. The pedal should hold pressure for around 30 seconds.