Sticking Brake Caliper Piston

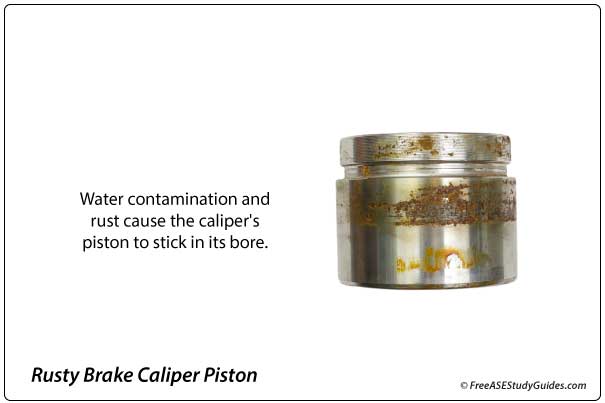

Water contamination results in a pitted, rusty caliper piston and bore. Caliper pistons are typically phenolic resin or chromed steel. The protective chrome and nickel plating wear off a steel piston. In addition, the piston bore becomes rusted and pitted from fluid contamination and dirt, resulting in a sticking or seized brake caliper piston.

Caliper pistons cause brake drag because the piston will not retract. As a result, the vehicle will pull or drift to the side with the stuck piston. This drag results in poor fuel mileage and an overheated brake unit.

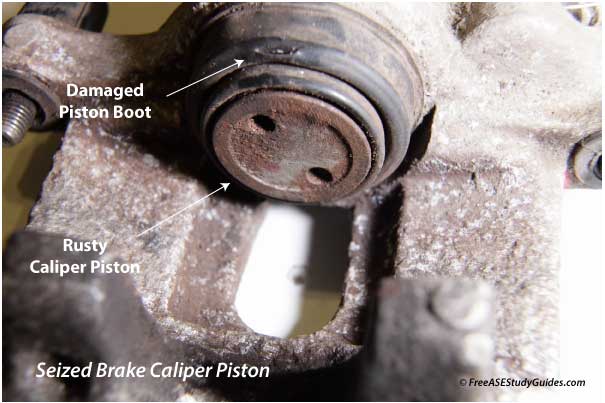

Each caliper unit contains a dust boot to protect it from road debris and water as the vehicle travels through puddles and dirt. Inspect the boot for wear when replacing the brake pads. Overhaul kits typically contain a new boot and seal.

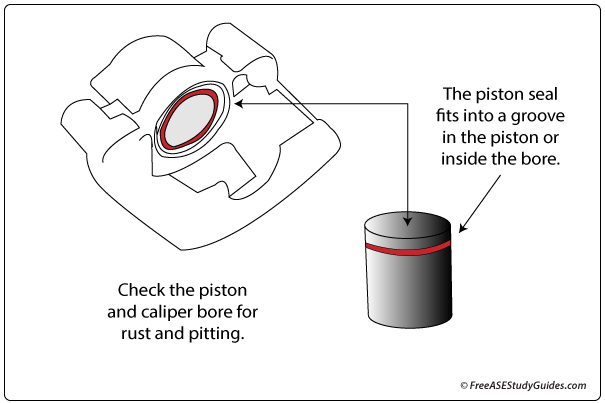

A low-drag brake caliper has a groove cut at a larger angle than a conventional caliper. A traditional caliper has a groove cut at around a 15° angle; a low drag system has a groove cut at a 30° angle. This design allows the seal to pull the piston further into the cylinder, providing less drag on the front brake calipers for greater fuel efficiency. These systems have become popular in many late-model vehicles.

Square-cut piston seals and other rubber components are sensitive to water, oil, and brake fluid contamination. Replace the protective dust boot and lubricate the piston seal with disc brake lube when rebuilding a brake caliper.

Environmental contamination and rust result in sticking or seized brake caliper pistons. Sometimes, it's cost-effective to replace the old rusty caliper with a new or remanufactured unit.