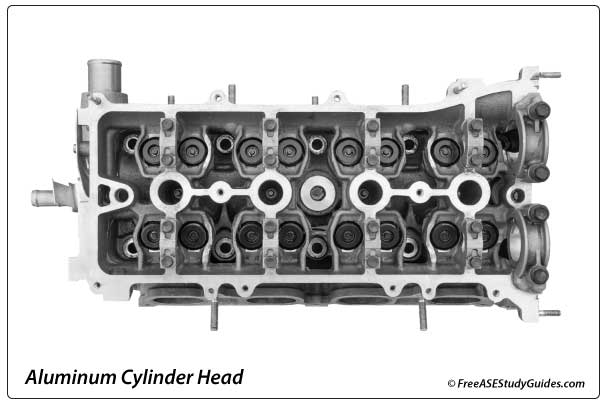

Cylinder Head Inspection

Clean the cylinder head before inspecting for cracks and damage. Remove old gasket material with a spray-on gasket remover and a plastic scraper. Clean cast iron heads in a hot tank with a caustic solution. Clean delicate aluminum heads with an appropriate degreaser and a small brush.

Cylinder heads tend to bow in the middle when overheated. Use a feeler gauge and a straight edge to check for warpage. Always check the manufacturer's specifications for allowable clearances.

Cylinder Head Crack Detection

Aluminum heads are checked using a dye that penetrates inside any cracks in the cylinder head. Clean the head's surface, spray the dye on, and let it sit for about 5 minutes. Wipe the surface with clean shop rags and apply the developer. Any cracks show up as red lines.

Pressure testing is done in a tank of water. Plates and inserts cover and seal all the ports and passages, and about three times coolant system pressure (30 psi.) is applied. Any cracks appear as tiny bubbles in the water.

Iron cylinder heads: Magnetic particle inspection or Magnafluxing® is the process used with ferrous or iron cylinder heads. A permanent magnet, cables, or probes create a magnetic field. Then fine magnetic particles are applied to the surface. A flux forms and the fine particles gather in the flaws or cracks in the head, revealing faults missed during a visual inspection.