Cylinder Leak Down Test

Run a cylinder leakage or leak down test after a cylinder compression test has verified a problem with the cylinder; a cylinder leakage test helps pinpoint the area of concern. It shows the percentage of leakage and helps identify the part causing the compression leak.

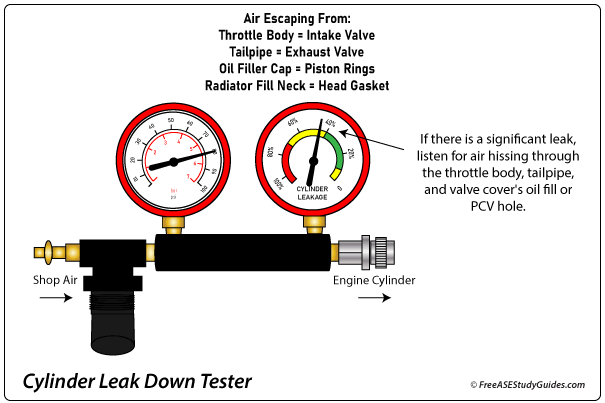

Cylinder Leak Down Tester

A cylinder leak down tester measures the amount of air pressure loss as a percentage. Typical testers indicate a problem when leakage exceeds 30-40%.

Safety Tip: Be careful when introducing air pressure into the cylinder; the piston can suddenly travel downward. The resistance from the other spark plugs helps resist this downward movement.

Diagnosing Cylinder Leakage

If there is a significant leak, listen for air hissing through the throttle body, tailpipe, and valve cover's oil fill or PCV valve hole.

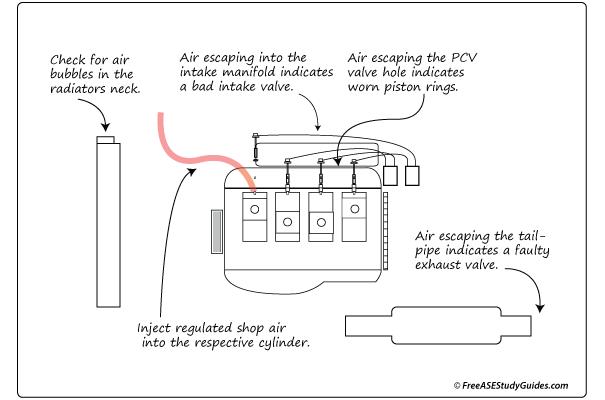

Leaking Intake Valve: A hissing sound from the throttle body indicates a problem with the intake valve. It allows compression to seep past the valve and its corresponding seat.

Leaking Exhaust Valve: Listen for air escaping through the tailpipe, indicating a problem with a worn or burned exhaust valve. The air/fuel charge helps cool the valve in multiport fuel injected engines. Therefore, the exhaust valves are more likely to burn with multiport injection.

Worn Piston Rings: Air escaping through the oil fill cap indicates worn piston rings. If all the piston rings fail the test in a high mileage engine, the engine is tired and needs new rings and bearings.

Leaking Head Gasket: Bubbles in the radiator neck indicate a leaking head gasket. The bubbles are from a compression leak between the water jacket and the cylinder. Engine overheating causes cylinder head warping and head gasket failure.