Engine Block Repair

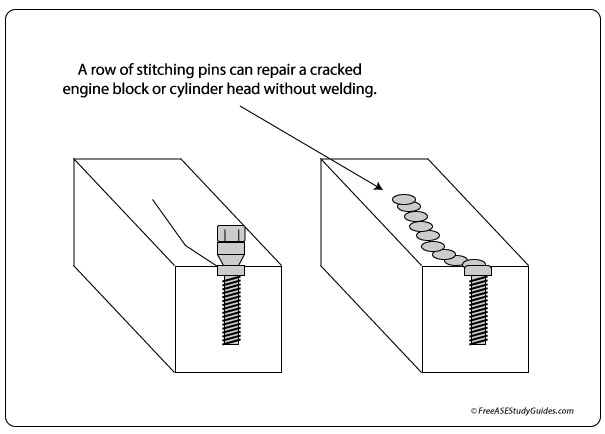

Most cast iron engine block repairs use metal stitching or pinning. Welding an engine block can be difficult due to high temperatures and special procedures and is best left to professional welders or someone with the appropriate skill set. There are easier and safer ways to repair cracks.

Pinning is a simple and effective way to repair iron engine blocks. These pinning kits use a bolt of the same material as the head or block to repair small and large cracks in cast iron cylinder heads and blocks. It typically requires a drill, tap, bolt, and grinder.

Here's how:

1. Always start at the ends of each crack. If it is long, take a punch and peen the crack at the ends.

2. Drill a hole at one of the ends using a bit that matches the bolt. These cracks usually reach into a coolant or oil jacket. Be sure to drill deep enough to repair the leak.

3. Ream a ridge around the bolt hole before inserting the bolt. These pinning kits typically have the proper tap provided.

4. Apply the thread lock or sealer and torque the bolt.

5. Grind the bolt close to the surface, and then peen the bolt again with a punch and hammer.

6. Smooth the bolt even with the surface.

Some kits include glue or epoxy to finish the bond. This method draws the two sides together, creating an almost undetectable repair. Follow any special procedures outlined in the kit.