Disc Brake Calipers

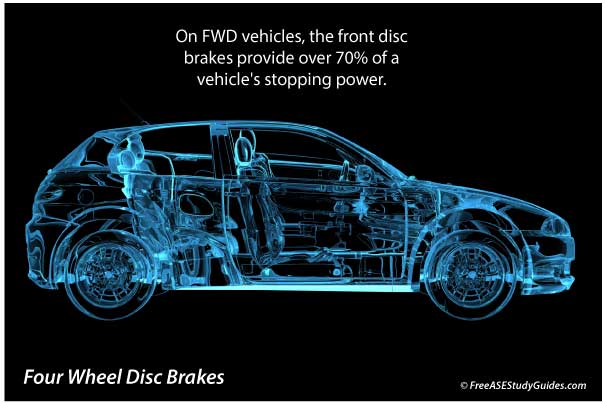

Manufacturers install four-wheel disc brakes on most light trucks and passenger cars. They are a better solution than the drum brake systems found on older vehicles. When braking, the vehicle's weight shifts to the front brakes. This extra work results in front brake pad and rotor wear. The front disc brakes on FWD vehicles provide over 70% of a vehicle's stopping power.

Fixed and Floating Brake Calipers

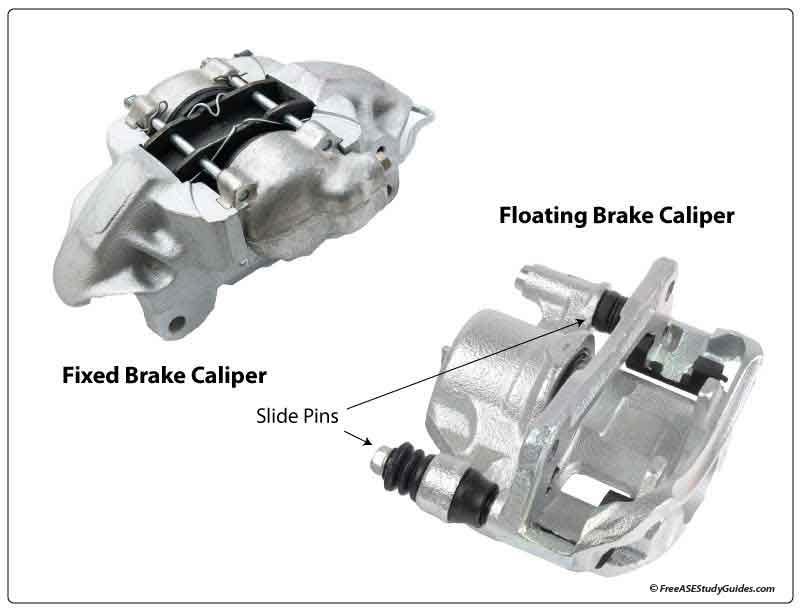

There are two types of brake calipers manufacturers install on automobiles and light trucks today. The most popular type is the floating caliper, which uses a single piston, the caliper body, and a sliding bracket to provide clamping force to the rotor. The other type is a fixed caliper that simultaneously uses two or more pistons to provide clamping power on both sides of the rotor.

Floating Brake Calipers

A floating caliper typically uses one piston to move the inboard pad into contact with the inner side of the rotor. The force of the inboard pad contacting the inside surface of the rotor causes the caliper to slide or float on the pins mounted to the bracket or steering knuckle. This action forces the outboard pad mounted inside the mounting bracket to contact the outboard side of the rotor. This clamping force on the spinning rotor causes the wheel to slow and stop.

The slide pins can stick in their bores, preventing sufficient braking force and causing the pad to drag and wear prematurely. As a result, while driving forward, the vehicle will drift or pull to the side with the dragging brake.

Fixed Brake Calipers

A fixed caliper has pistons on both sides of the rotor. These pistons squeeze the inboard and outboard pads with equal force, causing the vehicle to stop. Light/Medium trucks and luxury cars have fixed calipers.

Brake caliper pistons are either chrome-plated steel or phenolic plastic. Both of these are hollow to save weight. Phenolic pistons are excellent heat insulators and help prevent heat from degrading or boiling the brake fluid.