Hydroboost Brake Assist

Hydroboost brake units use power steering pressure instead of engine vacuum for brake assist. This booster is sometimes necessary if the engine does not create enough vacuum to assist the braking system. Diesel, turbocharged, and supercharged engines use these systems instead of vacuum brake assist units. Some manufacturers use an engine-driven vacuum pump to operate the vacuum booster instead of installing a Hydroboost brake system.

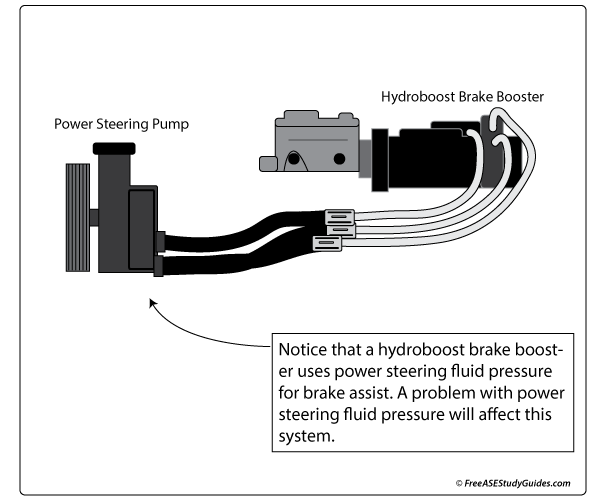

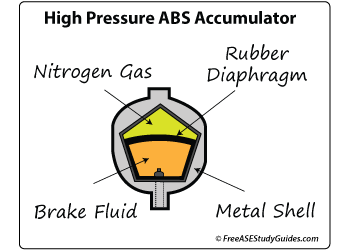

A Hydroboost unit is located between the firewall and the master cylinder, just like a vacuum booster. It has hydraulic lines leading from the power steering pump to the booster. It uses a spool valve and a power piston to regulate pressure. A spring-loaded or nitrogen gas-charged accumulator stores pressure in case of a power steering system failure.

Visually inspect the hydraulic lines and fittings for leaks. The hydraulic accumulator can be located internally in the power piston or externally on the booster unit. Be careful; an externally mounted accumulator is under pressure.

The power steering system and pump must be functioning correctly. If this system does not provide enough pressure to operate the Hydroboost unit, braking performance will be drastically reduced. Before proceeding, check the power steering system for pressure and flow.

Testing a Hydroboost unit is similar to diagnosing and testing a vacuum booster. With the engine off, pump the pedal several times. This action discharges the accumulator. Hold the pedal to the floor and maintain pressure on the pedal while starting the engine. The pedal should move slightly toward the floorboard and back toward your foot.

* It is important to remember that the power steering pump provides hydraulic pressure to the Hydroboost brake system.