Manual Transmission Countershafts

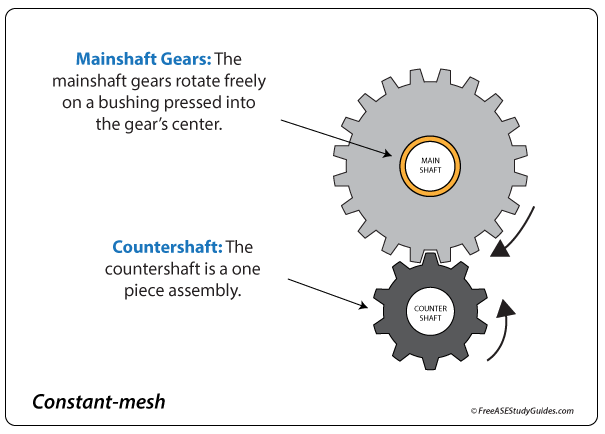

Countershafts are shafts with helical gears cast from a single piece of hardened steel. It transfers power flow from the input shaft drive gear to the gears on the output shaft. The gears and the countershaft rotate as one and are a one-piece assembly.

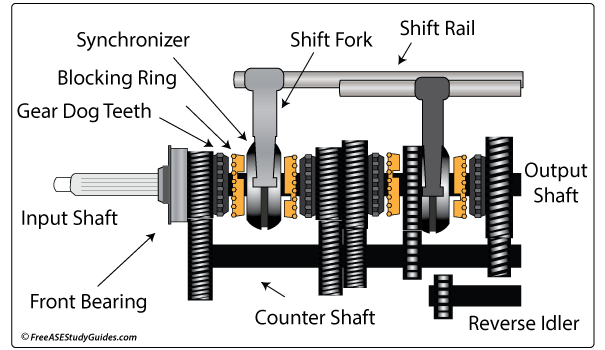

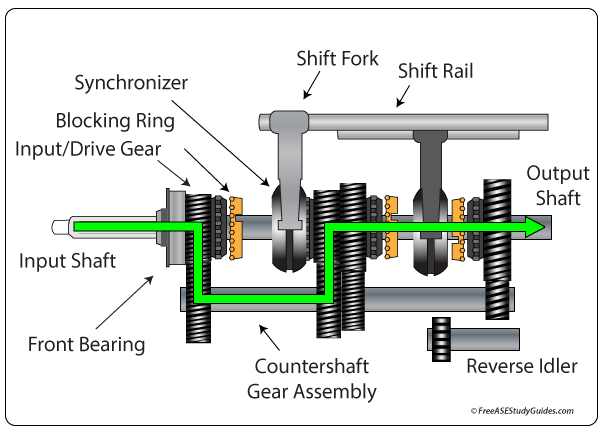

The largest and first gear is in constant mesh with the input shaft's drive gear, and the other gears are either reduction (low) or overdrive (high). Notice the power flow through the countershaft as the synchronizer locks a main shaft gear to the output shaft above.

In a constant mesh (modern) transmission, the gears on the main shaft (output shaft) spin freely on the shaft. A bushing is pressed into the center of each gear to reduce friction. A synchronizer slides along the shaft and locks the gear to the shaft to produce output.

A manual transmission connects the input shaft to the output shaft for a 1:1 connection.

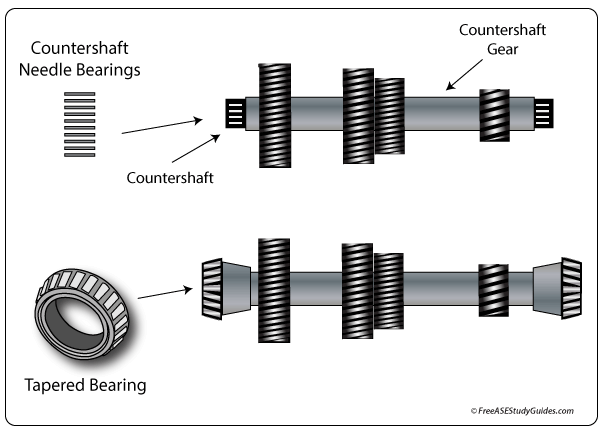

Some countershafts have a solid countershaft fixed to the case; it is fastened and does not spin. A countershaft gear assembly rides on needle bearings between the countershaft and the gear cluster. Another type of countershaft contains tapered roller bearings. Both require shims or thrust washers to control endplay.