Replacing Brake Lines and Hoses

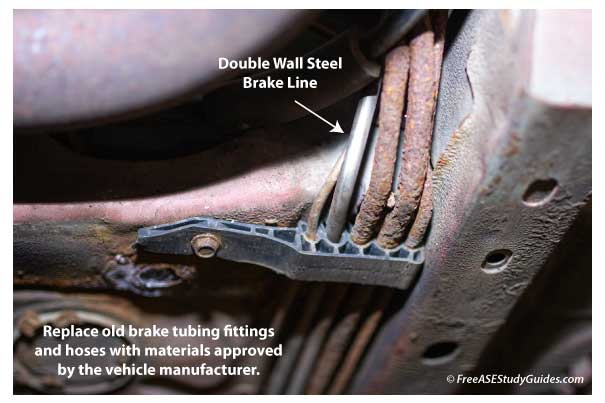

Most automakers use double-walled steel tubing as their standard OEM brake line. Brake lines and flexible hoses transmit fluid pressure from the master cylinder to the wheel braking units. The internal copper brazing and the external coating wear from use and time. Replace the brake line if it is rusty, kinked, or damaged internally or externally.

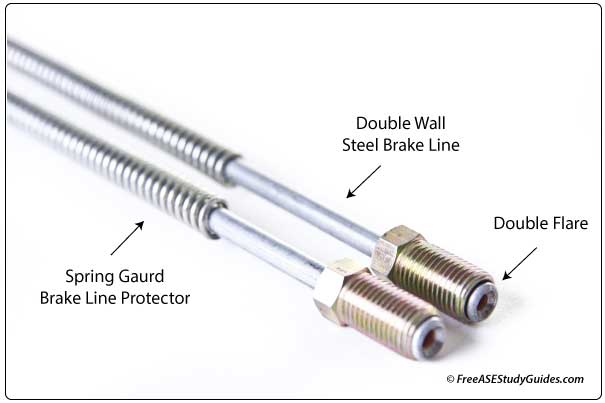

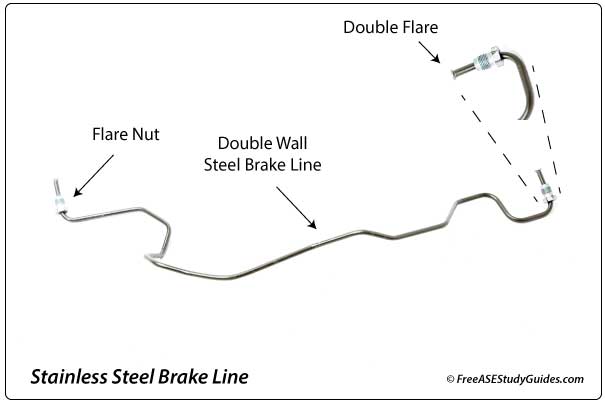

The line consists of two steel tubes welded at the seams and coated with tin or alloy to prevent corrosion. The ends of brake lines are flared at an angle to compress or crush into their companion seat. These fittings must withstand hydraulic pressures from several hundred to over 2000 psi.

It's always best to replace a rusted or damaged line with a preformed line designed for the vehicle. Never use compression fittings on brake lines. Tools are available to bend the tubing and create the flared fittings when the original lines are unavailable.

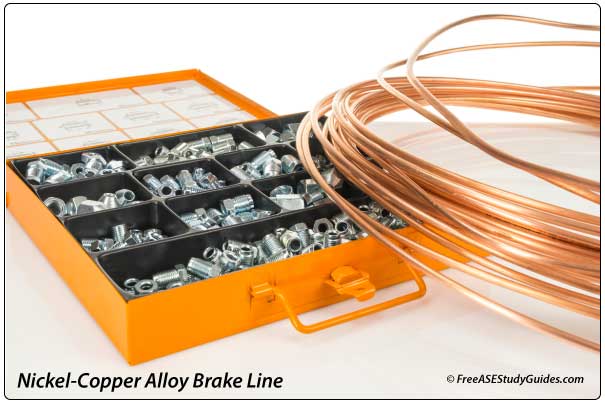

Manufacturers and fabricators use different tubing depending on the application. Tube bending and flare tools are available to fabricate brake lines. Patience and practice are required to bend and flare brake tubing.

Steel, stainless steel, and nickel-copper alloy (never 100% copper) tubing is standard. Some special applications have a nickel-copper line, which is easier to bend and flare. Copper tubing (100%) and compression fittings can leak or burst under intense hydraulic pressures.

Brake hoses

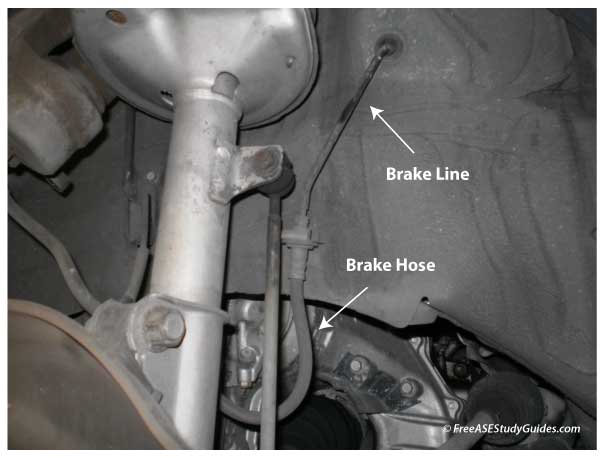

Brake lines fasten to the chassis or frame with fasteners to reduce vibration and a horseshoe clip where it meets the flexible hose. Brake hoses allow movement as the front wheels pivot, or the rear axle moves over bumps in the road. However, these hoses can swell or become brittle and crack, causing them to leak.

Brake hoses should always be replaced, not repaired. For example, the old brass washers that fasten the hose to the caliper should always be discarded and replaced with new ones. Also, never use brake tubing fittings or hoses not approved by the vehicle manufacturer.