Rack and Pinion Steering

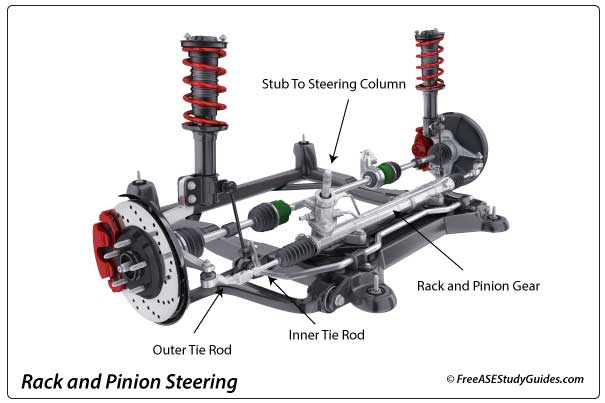

Modern passenger vehicles have replaced the steering gear box and parallel linkage with a power rack and pinion steering gear assembly. They have less linkage, better stability, and more responsive braking, with only an inner tie rod attached to each end of the gear. Today's vehicles have evolved from manual to hydraulic or electric power steering.

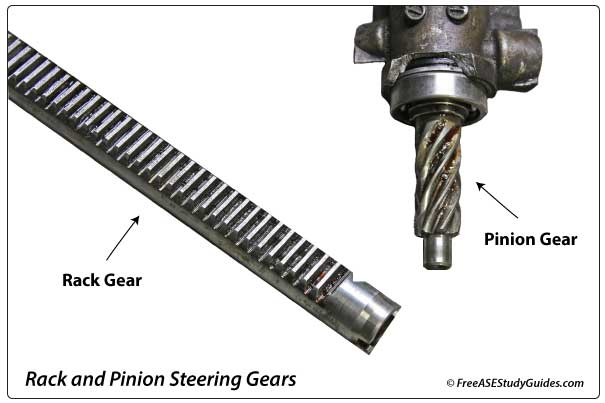

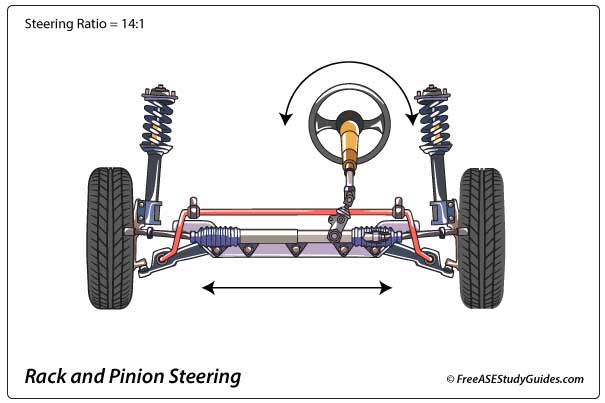

The universal steering shaft joint on the steering column connects to the stub on the pinion gear, and the pinion gear is in constant mesh with the rack gear. Rotating the pinion gear moves the rack gear linearly in a sideways motion.

This action moves the steering arms, turning the wheels. Rack and pinion gears translate the circular motion from the steering wheel to the linear motion that turns the front wheels. Steering gears are responsible for the steering gear ratio. Most steering wheels rotate three or four complete revolutions from stop to stop.

Teeth on the rack or pinion gear can fracture or flatten from heat and overloading, resulting in a skip or bind in the steering rotation at that point only.

Power Steering Fluid Leaks

Hydraulic rack and pinion power steering systems can form leaks in the pressure hoses, connections, power steering pump, and seals. As a preliminary inspection, check the fluid level in the reservoir and inspect the pump, hoses, and connections for leakage and wet spots.

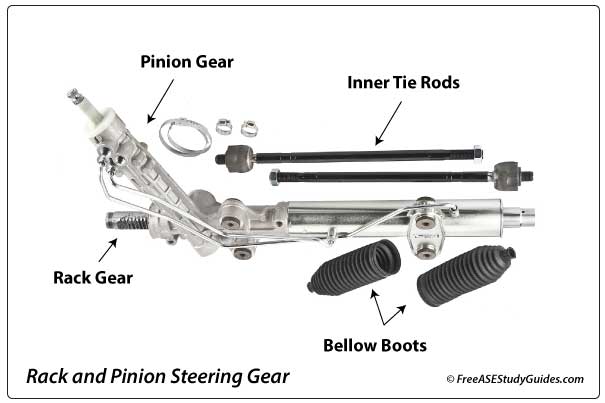

A control valve in the assembly directs pressurized hydraulic fluid to a sealed piston to assist rack movement left or right. Seals at the ends of the rack allow for movement and contain power steering fluid in the housing. However, it is common for the seals at the end of the gear assembly to fail from wear and cracking.

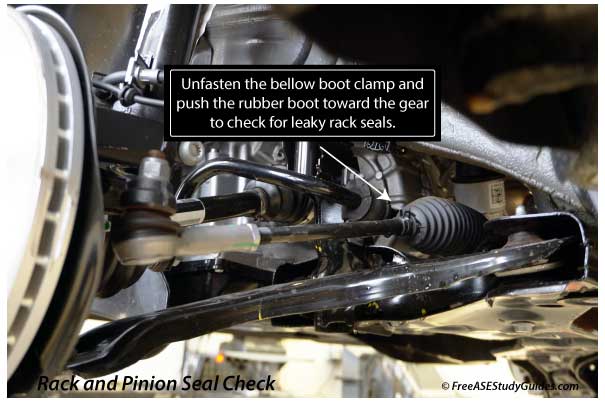

Leaking rack seals (bulkhead seals) result in power steering fluid collecting inside the bellow boot. Check the rack seals for leaks by detaching the bellow boot clamp and compressing and pushing the rubber boot toward the rack. Fluid dripping or squirting from the boot indicates a leaking seal. They are hard to rebuild, and replacing the old assembly with a remanufactured one is standard.

Electric Power Steering

Electric power assist steering systems use a reversible electric motor to assist in steering effort instead of hydraulic fluid pressure. The electric motor may be on the steering column or the rack. The control module receives input from the steering torque, steering angle, and speed sensors to control the voltage and direction of current sent to the motor.

More voltage is needed to assist steering effort when the driver travels slowly or negotiates parking maneuvers. As the vehicle travels faster, less assistance is required, and less voltage is needed. The EPS provides extra assistance to the driver while parking and less for a better road feel at highway speeds.