Ball Joint Inspection and Diagnosis

Ball joints fasten the steering knuckle to the control arm, providing a pivot point for steering and up and down movement as the vehicle travels over bumps. A worn ball joint makes a thunking or popping noise when the vehicle hits a bump or turns at low speeds.

Conventional SLA suspension systems found on trucks and many rear-wheel-drive vehicles contain two ball joints: an upper and a lower. The vehicle's weight transfers through the load-bearing ball joint. The other ball joint is considered the follower ball joint. The lower ball joint on a vehicle with MacPherson struts is a follower joint. Because load-bearing ball joints carry vehicle weight, they usually wear first.

If the coil spring is seated between the frame and the lower control arm, the lower ball joint is the load-carrying joint. To unload the lower ball joint, place a jack under the lower control arm close to the ball joint and raise the tire off the ground about two inches.

If the coil is seated between the upper control arm and the frame, the upper ball joint is the load-carrying joint. In this case, place the jack under the frame instead.

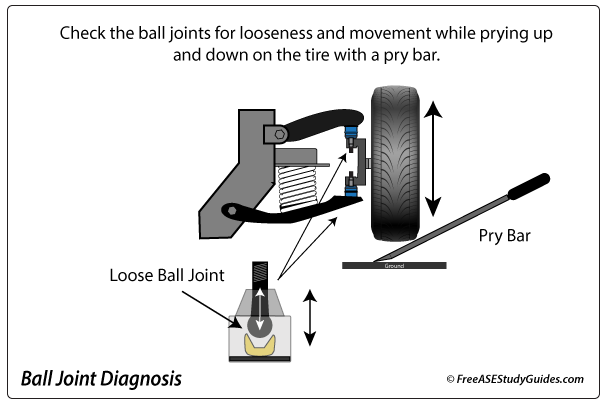

Check for Looseness and Wear

Ball joints should be tight. Rock the tire up and down and in and out to check for excessive movement. Like most end play measurements, use a dial indicator for precise measurements; as a rule of thumb, the reading should not exceed .050".

Today's ball joints usually have a plastic insert and do not contain a grease fitting. Some ball joints contain a wear indicator and need replacement when grease fitting extends out from the base of the joint. Others need replacement when the fitting wiggles or sinks into the base of the joint. Check with the vehicle's manufacturer for details.