Wheel Speed Sensors

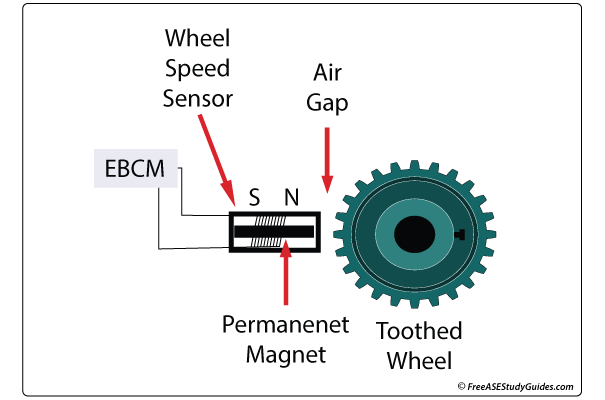

The ABS controller uses wheel speed sensors to detect the rotational speed of each wheel. They're a permanent magnet sensor, a coil of wire wound around a metal core. The magnetic lines of flux created by this sensor change as a toothed ring rotates past its tip. They create voltage pulses that increase with wheel speed.

If a wheel were to lock up, inducing a skid, the ABS unit would sense this decrease in frequency and activate the appropriate solenoid, momentarily removing hydraulic pressure from the brake unit. This drop in hydraulic pressure allows the wheel to spin instead of skidding.

Four-channel ABS systems in today's vehicles have a wheel speed sensor (WSS) at each wheel. A small bolt fastens the sensor, and a toothed ring is mounted to the CV joint, wheel hub, or differential ring gear.

If a code indicates a problem with one of the wheel speed sensors, inspect the wiring and tip for debris and the sensor's ring for damage. They're magnetic, metal debris can collect at the tip, and the reluctor wheel can become damaged or caked with dirt or clay.

Use a multimeter to troubleshoot an open (OL) or short (0.00) in the sensor. Test the sensor with the meter set to AC voltage. The voltage signal on the multimeter's display should fluctuate as the wheel or hub is rotated.